This summer Intech Services has provided a series of blogs dedicated to the Teflon™ coating selection process. In order to select the right product for your coating job, there are three important areas that need to be understood:

- Understanding the Project

- Understanding the Part

- Understanding the End-Use Environment

Within each of these areas are vital questions that need to be answered to ensure the most effective coating for the job at hand.

The third and final newsletter in the summer series will focus on Understanding the End-Use Environment.

Understanding the End-Use Environment:

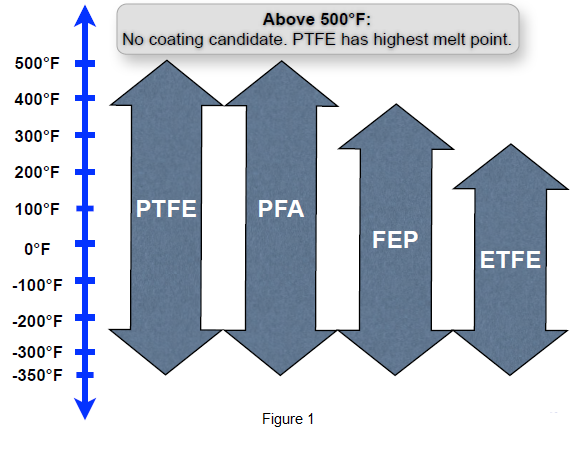

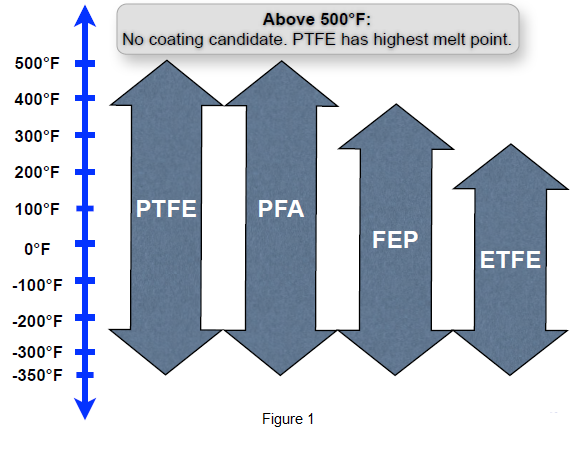

- What is the end-use service temperature?

- Will there be chemical exposure?

- Weak acids and bases: PFA, ETFE, or One Coats

- Srong acids and bases: PFA or ETFE with thicker DFT

- Vapors and permeation issues: Filled ETFE or PFA

- Will the part be in contact with food?

- All product lines have FDA-conforming products.

- Primer and topcoats must all be FDA-conforming.

- Are there any abrasion/durability concerns?

- PFA and ETFE: Very tough with thick film capability

- Ceramic reinforced specialty systems: 857G-040, 857G-140, and 857G-240

- Filled PFA powder: Knight Armor PFA 532G-13032

- PTFE One Coats: 958G-406 Abrasion Resistant Black and 958G-414 “The Green Monster”

For additional resources on the coating selection process please contact us directly at 302-366-8530, refer to the Compass Corrosion Guide, or refer to our Comparative Property Chart.