Fluoropolymer Sustainability and Responsible Manufacturing to Support Cable and Connectivity

Speaker Bio: Bianca Hydutsky, Global Technology Director – Advanced Performance Materials, The Chemours Company

Register Now

Abstract: Regulatory activity targeting fluorinated materials has increased globally, which may impact the ability to select and utilize the optimal materials to achieve performance and safety criteria in cable and connectivity designs. Many essential use cases have been identified both for safety and performance across a wide range of applications, such as, clean energy, transportation, aerospace, automation, advanced electronics, oil & gas, defense, security, medical, pharma, and more.

There are many questions and misconceptions across these industries, ranging from the chemistries of such materials to the development and deployment of responsible manufacturing technologies.

This work provides an overview of the regulatory landscape, examples of fluoropolymer materials of critical essentiality, and a deeper understanding of the sustainability impact of responsible manufacturing investments and analytical expertise needed to move forward.

About the Presenter: Dr. Bianca Hydutsky is the Global Technology Director for the Advanced Performance Materials Division of The Chemours Company, LLC. She received her B.S. in Chemistry from Millersville University and Ph.D. in Chemistry from The Pennsylvania State University.

The safety and quality of our products are top priorities, and that includes protecting them during colder months. Starting October 15, 2024, we are entering our annual Freeze Protect Season, which will run through April 15, 2025.

During this period, we implement additional packaging and shipping services to ensure our customers’ shipments remain unaffected by freezing temperatures. This applies to the following product lines (by prefix): 459G, 699N, 850G, 851G, 852G, 855G, 856G, 857G, 858G, and 953G.

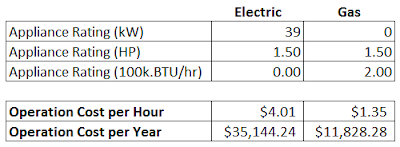

Freeze Protect Services and Fees:

- Freeze Protect Fee: A $39.00 per box over-pack charge will be applied to all shipments, and $39.00 per shipment for freeze protect services.

- Overnight Service: Available for critical shipments (except for product codes 850-7799 and 850G-204, which ship freight only).

Receiving Freeze Protected Shipments

When you receive a freeze-protected shipment, it’s crucial to follow the proper procedures:

- Check the product before signing the Bill of Lading. Open the box and inspect the product immediately.

- Check the freeze indicator: If the indicator is broken or turns blue/purple, the product may have been exposed to freezing temperatures.

- Do not reject the shipment: Instead, sign the Bill of Lading with the note, “Frozen Shipment Will Accept to Determine Extent of Damage.”

- Evaluate the product: Let it sit overnight, reincorporate the coating the next day, and assess the product.

- Notify Fluorogistx within 4 days of receiving the shipment if there’s any damage. Contact Corey Leigh at (302) 479-7734 or via email at leigh@fluorogistx.com.

Please ensure this information is shared with all relevant departments in your organization, including shipping, receiving, and procurement.

If you have questions about protecting your Teflon™ shipment, reach out through e-mail, phone, or by contact form on this websiste.

Fluorogistx is proud to share that Chemours is the recipient of a gold medal for their efforts in sustainability by EcoVadis, a sustainability management system. With the excellent rating on Chemours’ sustainable supply chain, Chemours is now in the top 5% of all responding companies.

According to the Corporative Responsibility Commitment goals articulated, Chemours is committed to a baseline sustainability performance of 80% suppliers by spend. This sustainable supply chain spans 9,000 suppliers across 60+ countries. Chemours plans to demonstrate a 15% improvement by the year 2030.

Read more about Chemours’ gold medal and efforts to keep supplies and sustainability at the forefront of their fulfilment.

The Environmental Protection Agency (EPA) hosted a comprehensive webinar on the TSCA 8(a) PFAS reporting obligations. It is recommended that all manufacturers (including importers) of PFAS and PFAS-containing products since 2011 review the webinar or its transcript. This reporting mandate is stipulated by the FY2020 National Defense Authorization Act.

For those seeking further insight into the TSCA 8(a) PFAS reporting requirements enacted in October 2023, additional information is available via an EPA-sponsored webinar accessible through this link.

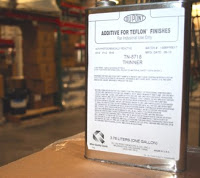

Below is a quick Q&A regarding purchasing Teflon™ coatings after the acquisition of Intech Services by Fluorogistx.

Q: Who do I contact for new orders? What about order status and tracking?

A: You can contact Patrick Garyantes to place new orders, check order status, and track your orders. E-mail him at Patrick.Garyantes@Fluorogistx.com You can callPatrick at 302-479-7614. If you prefer, you can fax new orders at 302-479-7618.

Q: When will orders ship?

A: Orders placed before 11:00AM will ship same day. All orders placed after will be shipped the next business day.

Q: Who are shipping carriers for ground and LTL shipments?

A: We typically use FED EX freight, XPO, A. Duie Pyle, etc. Depending on the location, however, customers can designate any shipping carriers for ground they wish.

Q: Certifications – what type of certs do you provide?

A: We will continue to provide certification of analysis and conformance.

Q: Are invoices mailed or emailed?

A: Depending on the customer’s prior communication and preferences, you will continue to receive invoices by mail or e-mail as you have in the past.

Q: Who do I contact regarding invoices and accounts payable?

A: You can contact Cathy Delaney for Invoices at Cathy.Delaney@Fluorogistx.com You can contact Marianne Morrow for accounts payable at Marianne.Morrow@Fluorogistx.com.

Q: How can I get a W-9?

A: E-mail PatrickGaryantes at Patrick.Garyantes@Fluorogistx.com for a W-9.

We are here to answer your most pressing questions about the Intech Services transition.

Q: Is Mike retiring?

A: No, Mike isn’t sailing off into the sunset yet. He will continue working with the Teflon™ team and customers at FGX to grow the industrial Teflon™ coatings business.

Q: Who is my sales representative, and who else is going with the move?

A: Mike Patterson, Chris Lord, and Steve Bucci will be moving to FGX and continue to be responsible for sales, technical support, and market development for the industrial coatings product line.

Q: How do I reach you by e-mail? Is there a new phone number?

A: You can contact our team through their Intech Services e-mails and phone numbers even after the sale. All e-mail and phone calls will be forwarded. You will receive e-mails from the new FGX e-mail addresses starting in May.

Q: Does this change of ownership mean there’s a price increase?

A: There will be no price increase associated with this transition.

Q: Do I need to reapply for credit at FGX? What will terms be?

A: No, you do not need to reapply for credit. Your terms stay the same and transfer with the sale.

Q: Did MOQs change? What about lead time for ordering?

A: No, there are no changes for MOQs, price, nor lead times for orders.

Q: Will we still be able to get material certifications?

A: Yes – we will still be able to provide Certifications of Conformance and Analysis.

Q: Can I buy online and what is happening with the Intech Marketplace?

A: You will have access to the Intech Marketplace and all e-commerce on our website until the end of April. Because FGX does not have the same backend support and software, you will not be able to purchase products from the Marketplace after the move. Our hope is to reopen the portal in the future. We encourage you to place orders for tapes, masking products, etc. ASAP!

Q: I have an invoice I need to pay. Where do I send the check?A: You can still send all checks to 211 Lake Drive Suite J Newark, DE 19702.

A: Any payments that arrive after we relocate will be forwarded to the new address.

Q: Any recommendations for customers?

A: Yes. Buying inventory in April will guarantee you have product on hand through the move. While we don’t anticipate a disruption in deliveries and service, it is still a good idea to stock up.

Q: What if I have specific questions about ordering and operations?

A: Our next email will cover more details. We will also be providing the new W9 for FGX in the near future.

Did we get your question answered? If not, let us know what it is, and we’ll add it to our blog post. Check back for more Q&As as we get closer to a final sale.

After 31 years of business as the exclusive distributor of Teflon™ industrial coatings, Intech has been acquired by fellow Chemours’ channel partner, Fluorogistx (FGX).

As the exclusive distributor for Chemours™ Fluoropolymer resins and dispersions in the United States and Canada since 2009, Fluorogistx services a broad spectrum of industries including aerospace, chemical processing, and data communication.

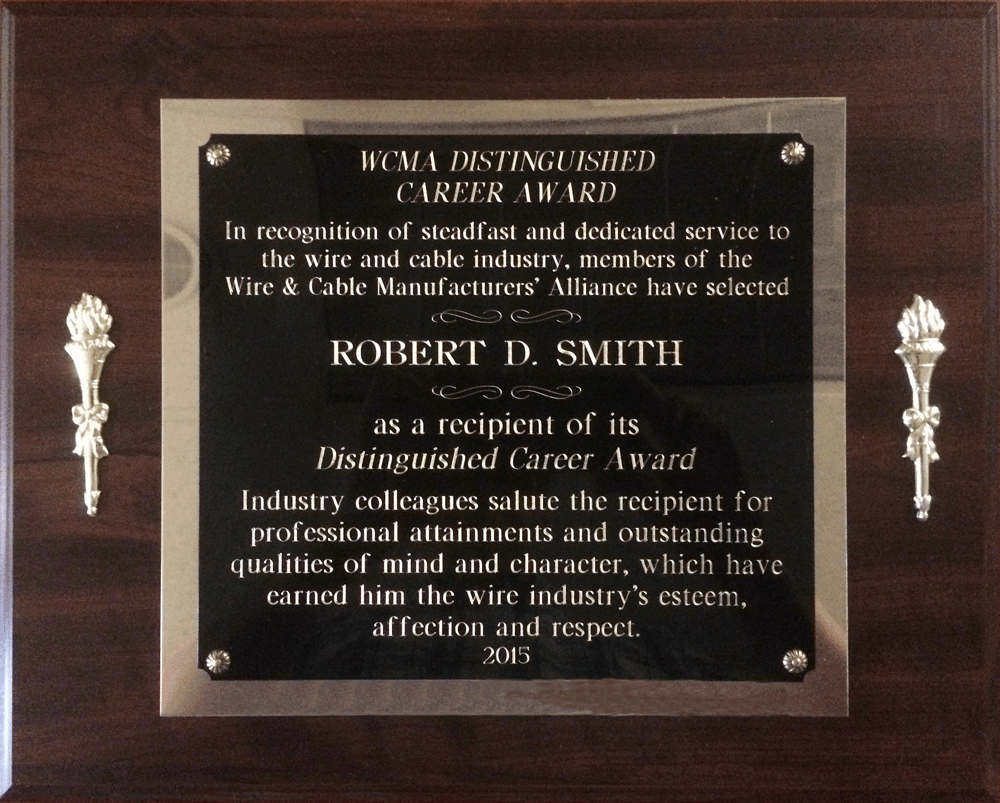

Bob Smith, President of Fluorogistx, joined the company in 2012. Some of you may know him from his 32 years at DuPont managing Teflon ™ businesses. Bob has a well-deserved reputation for serving customers and supporting them through industry economic cycles, some of which have been very challenging.

Fluorogistx and Intech Services share a similar long-term legacy of serving North American customers on behalf of Chemours™. Combining the two entities will create an even stronger market presence and further our ability to meet the needs of our customers in the future.

We are in the process of putting together an extensive list of answers to questions you may have about this transition and how it will affect you. The important takeaways now include:

- Expected transition date is May 1, 2023.

- Intech Services will continue to take and fulfill orders through the end of April.

- There is no price increase for Teflon™ coatings planned.

- Throughout the transition, all open orders and backorders will be fulfilled seamlessly.

- Our team will continue to provide the same excellent product and technical support.

- Fast, reliable shipping will continue.

- The Intech Services name will be retired, and all future business will conducted under Fluorogistx.

Keep your eyes open for more details in the near future.

On behalf of the entire team at Intech, I am very proud of the work we have done at Intech Services and the growth we’ve fostered over the past 31 years. This transition marks an exciting, new chapter for all of us involved, and we will continue to earn your business by providing the same excellence in service and support that you have been accustomed to for the last three decades.

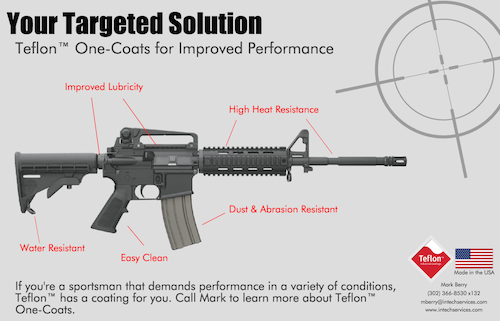

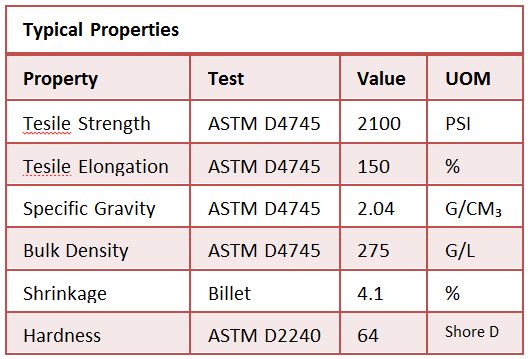

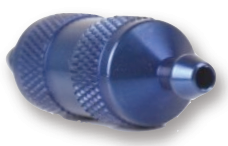

Intech Services, the Newark, Delaware-based pioneers and sole sellers of Teflon™ coatings in North America, have announced the launch of a new coating material to rival Cerakote for recreational, tactical and military firearms.

The product launch represents the culmination of years of research and product development by Intech and their partners Chemours.

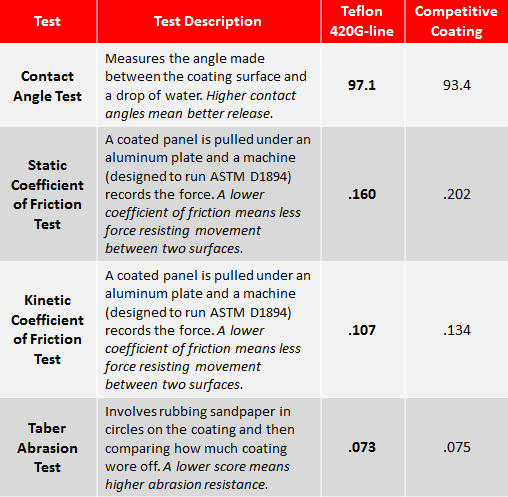

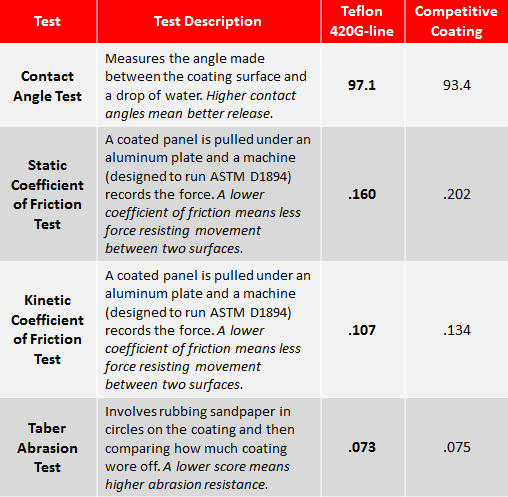

Designed to supersede and improve upon the industry standard Cerakote material, Intech Services’ new Teflon™ based coating material promises to improve the overall performance of hand guns, rifles, and shotguns. In particular, their new technologically advanced coating material ensures a low coefficient of friction surface, corrosion resistance and increased durability.

Firearm manufacturers, owners and enthusiasts will also note reduced jamming, reduced sliding friction, reduced carbon fouling and the elimination of rust for firearms. The superior Teflon™ based technology also guarantees a high quality flawless finish and is available in low gloss, rich colors such as Desert Tan, Drab Green and Matte Black.

With its smooth application, shorter oven cure time, and 20+ year UV resistance, Intech Services and Chemours believe they are providing the most superior firearm coating material in the North American market.

Intech Services has been the sole US & Canadian seller and distributor for Teflon™ industrial coatings for 30 years. They are constantly focusing on growth through market development, innovation, service, and support. Through their partnership with Chemours, Intech is determined to provide the highest quality and performing coatings to their customers.

Intech is the exclusive distributor of this new firearm coating technology. They offer online ordering, fast shipping, and competitive pricing for customers across the United States and Canada.

A spokesperson for the company said, “Intech Services goes beyond the transaction. When you purchase with us, you also get access to our world-class support. Our business is comprised of friendly, knowledgeable people that can offer technical support, troubleshoot application issues, provide failure analysis and more. We are here to help you coat more, better.”

More information on their new firearm coating material is available at https://fluorogistx.com/teflon-ptfe-dry-film-lubricants

Do you work in the industrial coatings industry? What marketing and sales techniques do you currently use? Are they working for you? Do you want to hear from like-minded individuals and industry professionals? If you are ready to take your business to the next level, this is the YouTube talk show for you!

‘Deliver More’ is the name of the new talk show, which was created to fill the media void within the coatings industry in Canada and the US. Intech Services understands the challenges faced by you and other industrial manufacturers, and how difficult they can be to manage as these issues rarely gain mainstream attention.

You can view more information here.

If you want to listen to quality conversations on the issues that matter most to you in the coatings industry, this is the monthly YouTube talk show for you. In each episode, the hosts invite different guests to offer advice so you can take your company to the next level.

‘Customer Service with Monica Trout’ is the latest episode and focuses on the importance of quality customer service. During the show, the global health crisis is discussed alongside the ways it has highlighted the need for regular customer updates.

You can view more about Intech Services at https://fluorogistx.com

Intech Services provide support via email and telephone to ensure customers can reach them when they need to, through their preferred medium. As you may be aware, a key challenge being faced by the industry, and manufacturers around the world, is supply chain issues.

A lack of raw materials is causing issues throughout the supply chain, which is having knock-on effects, including product shortages. As the world reopens for business, these shortages are becoming more noticeable.

Monica states that there are tough conversations that need to be had between you and your customers to highlight the materials shortages and possible solutions. In these situations, she explains that giving your customers advance notice of the challenges can prevent dissatisfaction in the future.

It can also build trust and brand loyalty when your customers are listened to and supported, even when there may not be an immediate resolution.

A company spokesperson said: “The ‘Deliver More’ video series will cover a wide range of topics that will help you become a better, and more profitable, Teflon coater. If you have a specific Teflon coating technical question, call our Technical Team anytime at 1-302-366-8530.”

Go to the links provided to find out more, or click on https://anchor.fm/deliver-more so you can stream the podcast.

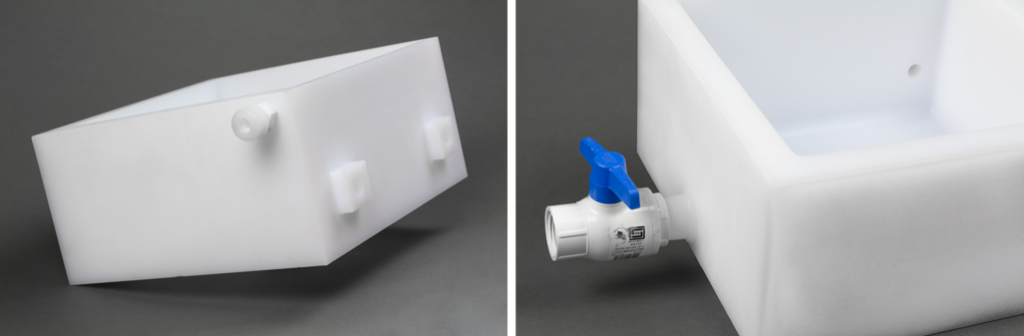

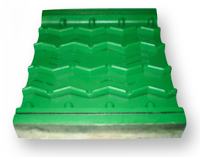

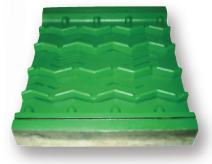

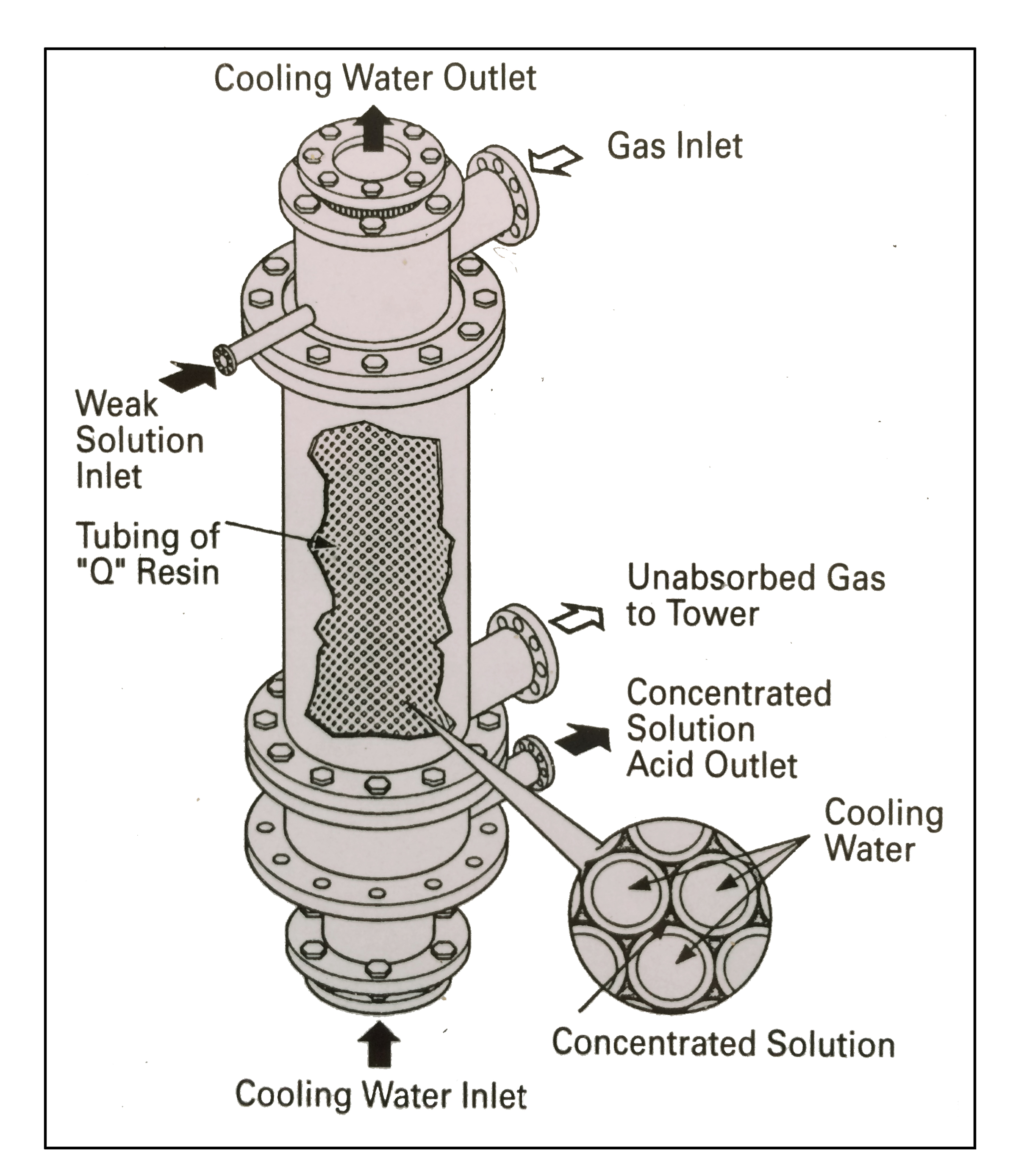

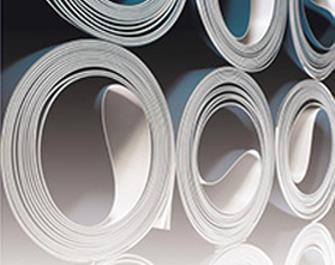

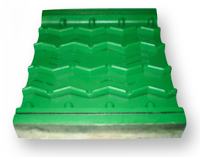

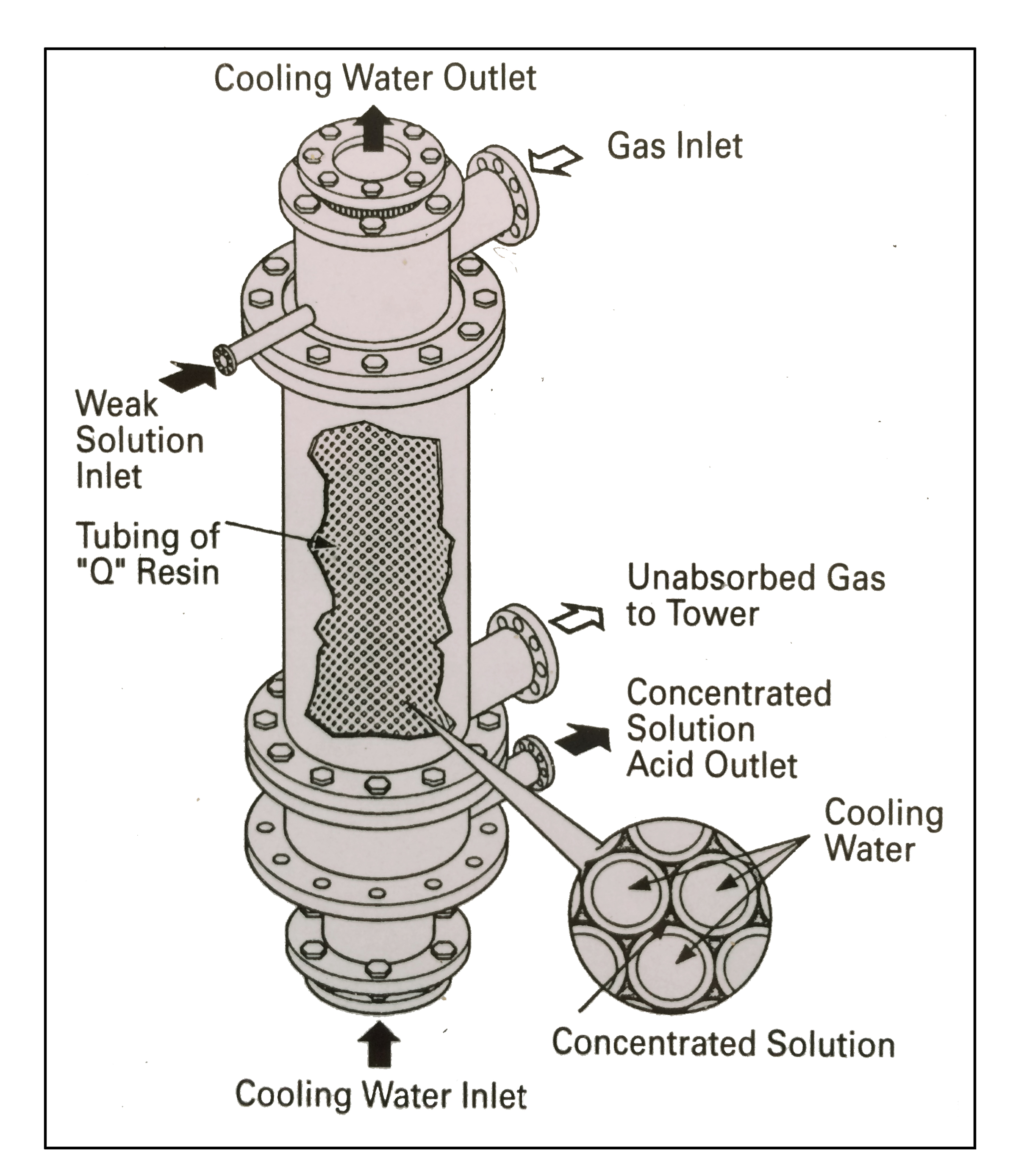

If you operate in the chemical, petro-chemical, mining, or semi-conductor industries, these EFTE coatings have been developed and tested with you in mind.

Replacement of parts is not an ideal solution when there are supply chain issues. Intech Services states that EFTE coatings provide you with a cost-effective alternative now and well into the future.

As you’re probably aware, Teflon™ is a household name when it comes to non-stick coatings. However, its use as an industrial coating, both in liquid and powder forms, is lesser-known. The various product families all use fluoropolymer technologies, which possess unique protective properties.

More specifically, the expanded line of ethylene tetrafluoroethylene (ETFE) products is designed to provide high corrosion resistance across a wide temperature range. Intech Services states that these qualities make them ideal for chemical processing applications.

Indeed, EFTE coatings are already widely used in the chemical industry. Teflon™ products are regularly exposed to acids, polymers, petrochemicals, and inorganics and have demonstrated excellent corrosion resistance and durability to date. With the latest range, the company provides you with the ability to reach thicknesses of between 80 and 100 mils, resulting in a greater degree of protection.

Some examples of places where you could apply the coatings include tanks, vessels, flanges, piping, impellors, manifolds, and reactors. While metal components and other treatments can be expensive, Intech Services states that the updated range provides you with a cost-effective solution.

About Intech Services

As the sole distributor of Teflon™ products in the US and Canada, Intech Services has embraced its position of leadership to provide a range of education programs in support of customers and suppliers. Workshops inform you on available products, emerging markets, and sales strategies. In addition to Teflon™, the company also supplies TCI powder coating, Mighty Hook, Gemma Powder Equipment, and Steelman Ovens.

A company representative stated:

“Intech’s long-term relationships are built on solid foundations of fast and courteous customer service. We look at our leadership role as a responsibility to help grow our coating customers’ capabilities and services and lift the industry as a whole in the process.”

Teflon™ is a household name for a good reason. Click here to learn more.

On this special edition of Deliver More we celebrate an important milestone for the company. To celebrate 30 years of business, we sit down for a talk with Mike & Bob Patterson to discuss the very beginning of Intech Services, and the vision that’s allowed the company to deliver more for 3 decades.

PTFE Zonyl™ Micropowders

Based on rigorous testing of representative samples, Chemours™ Zonyl™ PTFE Micropowders are certified to comply with Annex I to Regulation (EU REACH) 2019/1021.

Recently, the EU has taken measures to regulate PFOA, its salts and related substances in a wide range of products under the EU REACH program. The new regulation requires that, subject to certain exceptions, as of July 4, 2020, mixtures and articles placed on the market in the European Union will have to meet the concentration limits set under Annex I to Regulation (EU) 2019/1021 (EU Persistent Organic Pollutants Regulation). Based on rigorous testing of representative samples, Chemours™ Zonyl™ PTFE Micropowders comply with Annex I to Regulation (EU REACH) 2019/1021.

Currently Chemours™ offers multiple Micropowder offerings that meet the above regulation. For more information download the Zonyl Micropowder product brochure here.

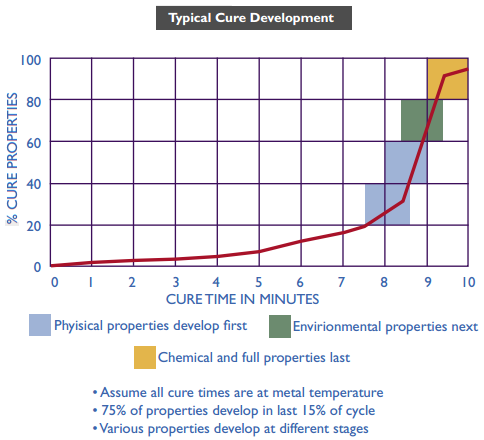

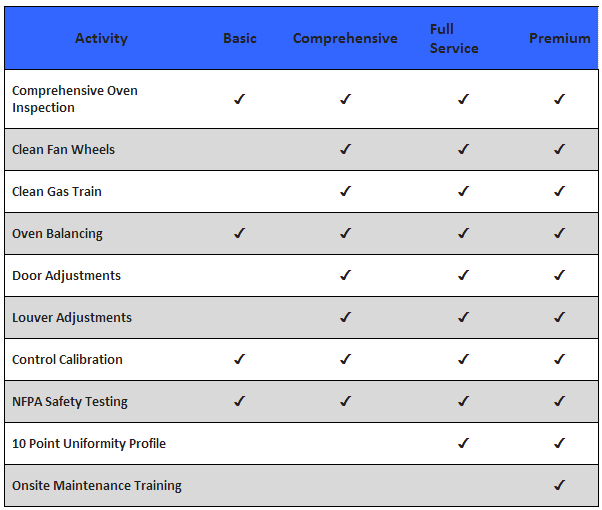

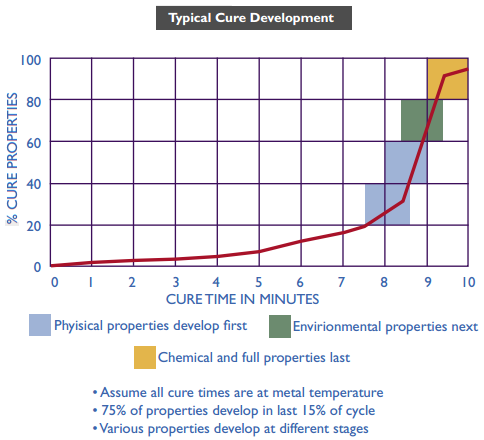

Curing is the last step to good adhesion of your Teflon™ coatings. Reaching and maintaining proper cure temperatures for a sufficient period of time to cure the coating is one of the most important factors in achieving a finish with optimal adhesion performance.

It’s important to remember that all temperatures mentioned in the Teflon™ Fact Sheets refer to metal temperatures, meaning that it’s the part itself must reach the recommended cure temperature. Ovens should be calibrated at least twice per year, and thermocouples should be used to check part temperatures. Each coating has different curing instructions, so always check the Fact Sheets first, and always follow the cure schedule very carefully.

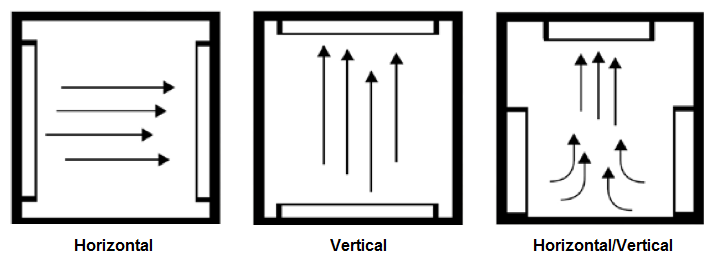

Class A Oven Curing

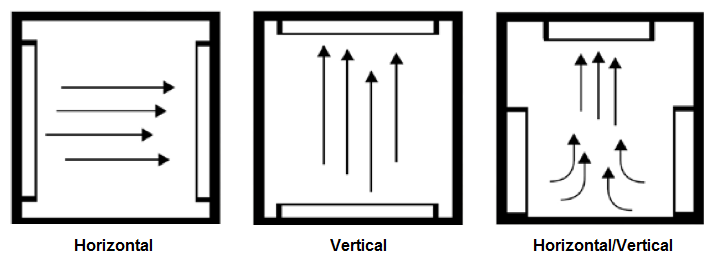

All commonly used types of industrial ovens are used for curing Teflon™ industrial coatings. Teflon™ coating systems are not affected by the combustion products of coal gas or natural gas, so direct fired gas ovens may be used. Both batch ovens and high production conveyorized ovens are used. Conveyorized ovens must be carefully designed to give accurate and uniform temperature control since maximum conveyor speed and minimum oven length are important economic factors which operate to reduce dwell time.

CONVECTION OVENS may be gas fired, direct or indirect, or heated by electrical resistance coils. Good circulation is required for uniform heating. Convection ovens require longer time to warm up than infrared ovens, and conveyorized systems require greater floor space for equivalent line speeds.

GAS AND ELECTRIC INFRARED OVENS offer the advantages of rapid transfer of radiant energy, ability to control speed of warm-up by placement of the radiant elements and reduced dwell time. It is less effective where coated parts are complex in shape, since infrared energy travels in a straight line and the intensity of heat is inversely related to the distance (squared) from the source, so inner crevices and angles will not cure at the same rate as outer surfaces facing the source. High velocity air may be used to make the air temperature more uniform.

Oven Safety

Ventilation of ovens is very important for the safety of workers. Ventilation is usually provided via an outdoor stack. Negative pressure should be maintained at all times with an inward draft at both the entrance and exit of the oven. Even the small amounts of decomposition products of fluoropolymers which occur at bake temperatures may cause discomfort to people in the area if the fumes are not vented to the outdoors and allowed to be diluted by the outside air.

Oven Calibration

Ovens should be calibrated at least twice per year, and thermocouples used on the parts themselves or in the oven at several locations, recognizing that air temperatures are of little value except when based on experience with a given oven and oven load over a period of time.

Factors which affect total bake time (including warm-up):

Time in oven

Heat capacity of oven

Mass and thermal conductivity of the substrate

Air circulation

Oven air temperature and/or radiant energy

Percent of substrate covered by Teflon™ (insulator)

Load of work in the oven

Weight to surface area ratio

Here’s an inexpensive oven calibration tool.

Troubleshooting Curing

OUTGASSING occurs with cast iron or cast metal substrates and can be prevented by preheating the part up to 250° F before applying the Teflon™ coating. Preheating the part will release all air that is trapped inside the substrate.

BRITTLENESS usually means the part was over-baked. When the Fact Sheet states the cure temperatures, it is referring to the actual metal part’s temperature. In order to assure that your part has reached the required cure temperature, use a thermocouple to measure the part temperature while curing.

ROUGH TEXTURE can happen when the part is under-baked. Teflon™ industrial coatings should be smooth and have a soft touch to them. Use a thermocouple to make sure the part temperature is correct. Another cause of under-baking can be poor oven calibration.

In previous blog posts, we’ve covered the common types of spray guns, choosing spray guns and keeping them clean, troubleshooting spray gun issues, and overcoming the Faraday Cage Effect. Here we’ll review some techniques that will help you save money while spraying and also how to choose which feed system and gun type will be best for your applications.

Film thickness consistency plays a big role in saving money in the coating shop. Having inconsistent thicknesses means you’re probably wasting coating, and therefore wasting money. By using these simple techniques, you’ll be able to cut out the waste, as well as achieve a better, more consistent finish for your application.’

1. Spray Distance

The spray distance is based on the spray equipment, coating, complexity of the part and spray environment. By keeping the gun at the same distance from the part the entire time you’re spraying, you can improve the consistency the film thickness over the whole part. Increasing the gun distance increases the pattern fan size, and the coating thickness decreases as it is distributed over a larger area.

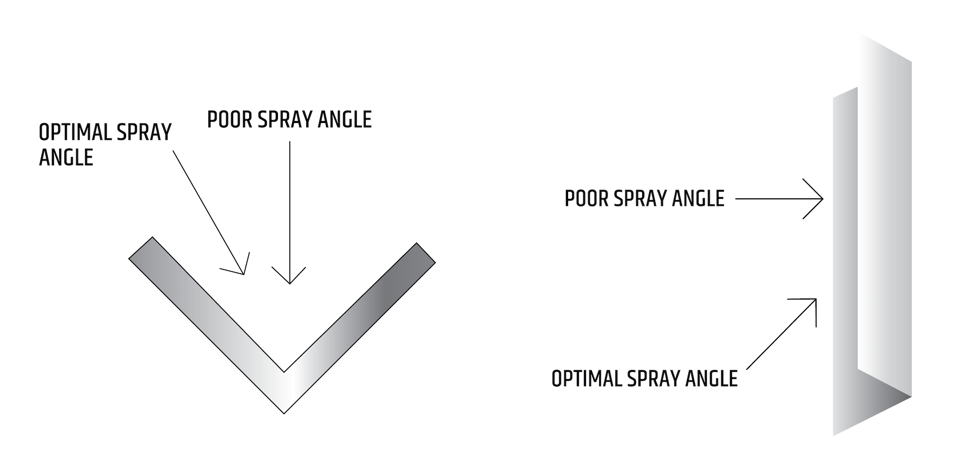

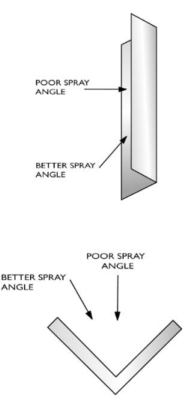

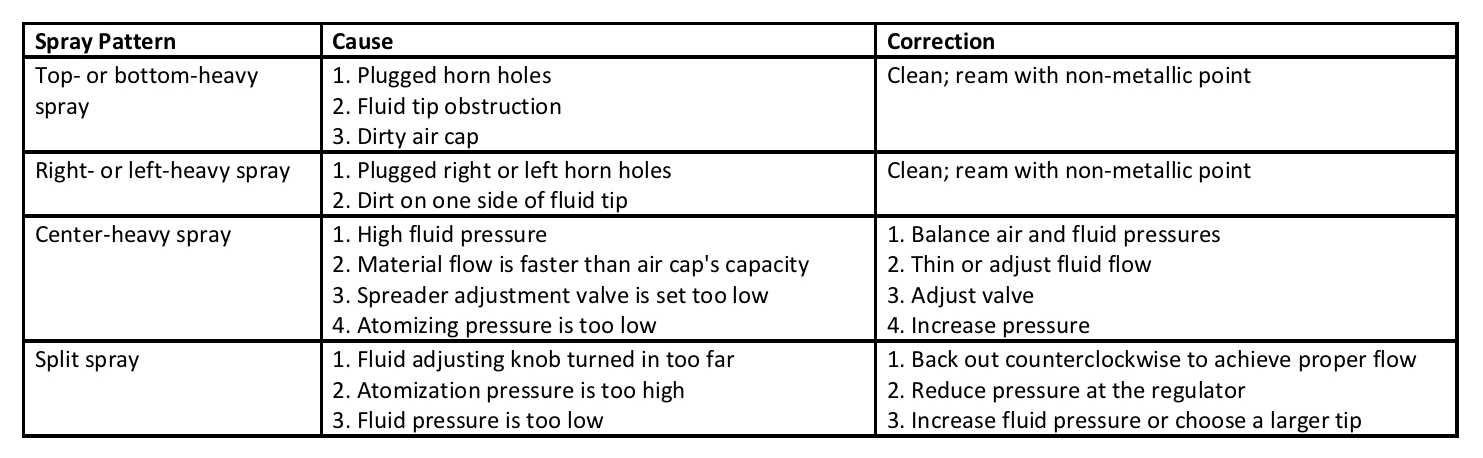

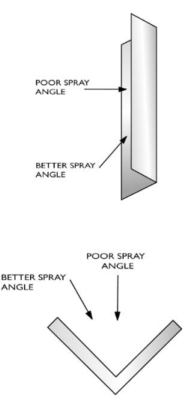

2. Gun Angle

Maintain controlled gun angle to the part. Yaw and pitch spray angles will result in a non-uniform spray pattern distribution, causing inconsistent film thicknesses.

3. Spray Pass Overlap

Each spray pass should overlap 50% to 75% of the previous pass. Overlapping below 50% results in “striping,” or variations in the film thickness. The more you increase the overlap, the thicker the coating, so overlapping above 75% requires more spray passes and more coating.

4. Spray Pass Speed

Adjust the spray gun speed to achieve consistent films. Before pulling the trigger, consider the coating flow rate and the target wet film thickness. Adjust the equipment before spraying to find a flow rate that lets the applicator move at a controllable, comfortable speed. Spraying too fast can lead to decreased film thickness, and sometimes extra coats will be needed to make up the deficit.

5. Trigger Control

Maintaining a consistent trigger pull on each spray pass directly impacts the flow rate, spray pattern size, and transfer efficiency. Start triggering immediately before the lead edge of the part and release the trigger immediately following the lag edge. Fully pulling the trigger provides constant flow rate control. The fluid knob on your spray gun can be adjusted to restrict the trigger travel distance so you can always pull the trigger all the way. Partial triggering, however, can be very useful for blending and touching up.

6. Edge Banding

Partially pull the trigger to spray a light coat around the edges of the part. Then spray the center of the part, blending the edges into the first coat. Banding can increase transfer efficiency and increase film thickness on the edges. This technique ensures the edges get coated completely while maintaining consistent film thicknesses.

Spray Gun Feed Systems

We have a large selection of spray guns with many combinations of gun platforms and feed systems. Here is some information to help you decide on the best feed system for your shop:

GRAVITY FEED SYSTEMS use cups attached to the top of the gun and use gravity to feed the coating into the gun. Gravity feed guns can have different coatings switched out quickly and require less pressure to operate. However, the cups are usually small and do not hold much coating, so they are best for coating small parts.

SIPHON FEED SYSTEMS use cups attached to the bottom of the gun and create a vacuum that sucks the coating into the gun. Siphon feed guns are heavier that gravity feed guns, but the cups hold more coating.

PRESSURE FEED SYSTEMS use pots that utilize air pressure to push the coating through a tube into the gun. No fluid can leak from the pot, so you don’t have to worry about wasting coating. The gun itself is lighter than gravity and siphon feed guns because there is no cup attached to the gun at all. You can also spray with the gun upside-down or at sharp angles and not worry about the coating coming out of the cup.

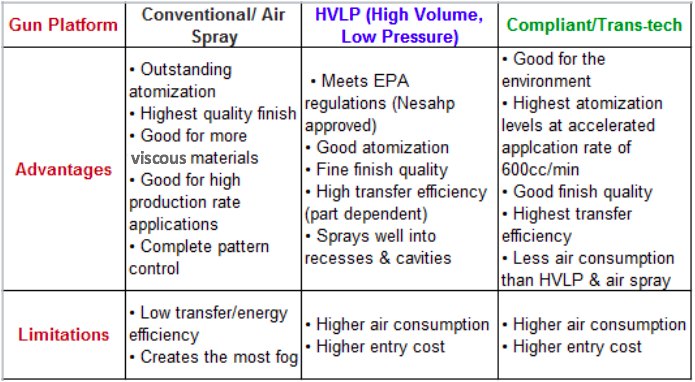

Choosing Spray Gun Types

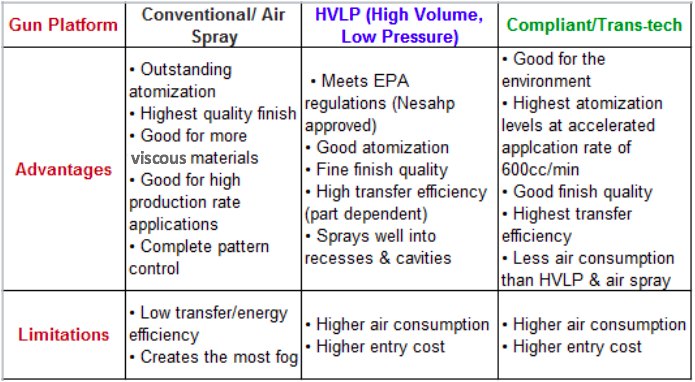

CONVENTIONAL SPRAY GUNS use a basic high pressure. The coating is blasted onto the part at this high pressure using an air compressor. The high pressure finely atomizes the spray giving the coating a very smooth finish. Transfer efficiency for Conventional spray guns is typically 50% or less.

HIGH-VOLUME LOW-PRESSURE (HVLP) spray guns increase transfer efficiency, typically to about 65%, meaning more of the coating actually makes it to the part instead of being wasted. With HVLP guns, air is delivered at much higher volume than conventional guns, but with a much lower pressure, so that more finish ends up on the part instead of in the air. HVLP guns are compliant with the California South Coast Air Quality Management District.

TRANS-TECH SPRAY GUNS use low volume, medium pressures. Transfer efficiencies are normally about 60% or better. Trans-tech guns are the best of both worlds: the finish quality is almost that of a conventional spray gun with close to the efficiency of an HVLP spray gun. Trans-Tech is used where compliance is not required but cost savings is important.

Here’s a handy chart for deciding between Conventional/Air Spray, HVLP, and Trans Tech/Compliant.

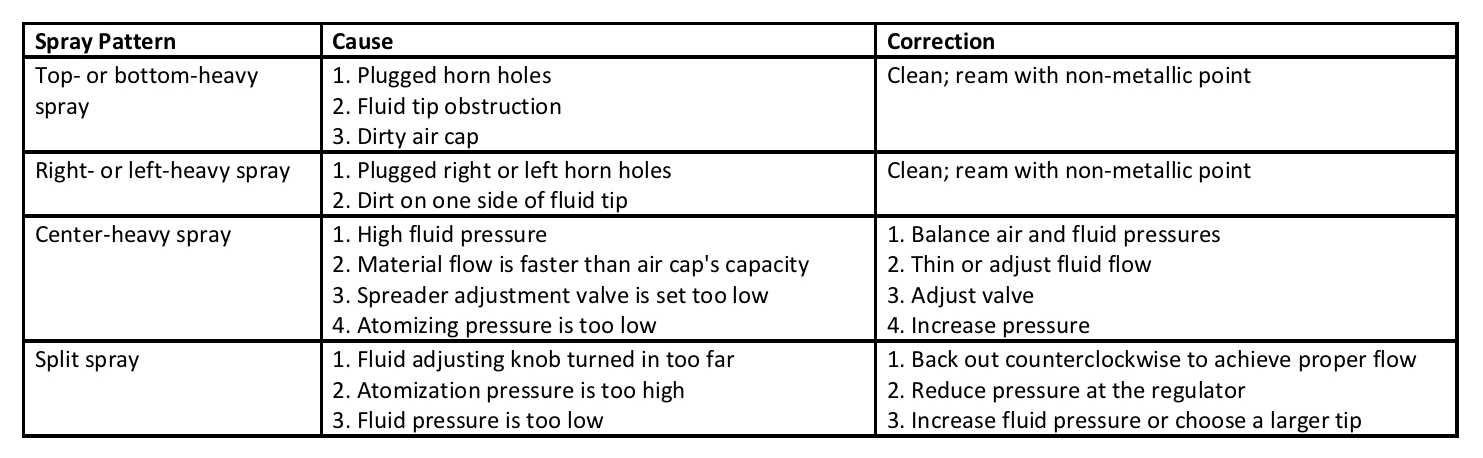

And more on Troubleshooting spray guns here.

How to overcome the Faraday Cage Effect.

…and more on the most common spraying methods.

Any Teflon™ industrial coating system is only as good as the prepared surface it is being applied to. Good adhesion can make or break the performance of a properly baked Teflon™ coating. The life of a coating can be directly related to the steps taken in cleaning and providing a good surface to adhere to. Find out the best substrates, proper surface preparation materials, and processes necessary to maximize adhesion results for Teflon™ coating systems in the “Application Overview” section of our website.

Are you thinking about upgrading your shop so you can apply Teflon™ coating systems? This can feel like an overwhelming task, but that’s where we come in.

As the sole distributor of Chemours Teflon™ industrial coatings for over 27 years, Intech Services has come to have a deep understanding of the coating process and the equipment needed to apply our coatings. And we have collected the best equipment for your coating business in our online Shop.

Essential Equipment for Coating

In this “Equipment Start-Up Guide,” we have put together a baseline estimate of what it would cost to start up your Teflon™ industrial coating operation. Whether you are a coating shop looking to expand business or if your company wants to bring an outsourced coating job in-house, this Guide provides the foundation of what you will need to get started.

The process for applying Chemours Teflon™ industrial coatings includes reincorporating solids in the coating by rolling, preparing the surface by grit blasting, spraying the coating with the correct spray equipment, and curing the coating in a Class A industrial oven. In order to achieve the optimal coating, each step is important and should be considered as you evaluate this process. This Guide covers it all’.

And our Technical Services Team is here to guide you through the process:

- Selecting the right equipment

- Selecting the right coatings

- Managing multiple vendors

- Reliable options and upfront pricing

- Convenient payment schedules

- Coordinating delivery and installation of new equipment

- Post-sale follow-up and service

Call the Technical Services Team anytime at: 302-366-8530.

Adelhelm LubriCoat NA was formed in 2018 when the Adelhelm Coaters Group acquired the remaining shares of Quality Coatings Inc. located in Mukwonago, WI. Adelhelm is a group of industrial coaters applying nonstick, dry film lubrication, and corrosion and chemical protection coatings. Chemours Company awards Licensed Industrial Applicator (LIA) certification to coaters that demonstrate consistently high quality control in operations and production.

The Adelhelm Group, established in 1971, has grown to an internationally recognized provider of engineered coating solutions in the automotive, aeronautic, medical, chemical, offshore, and food processing industries. Working closely with Tier 1 and 2 companies and other end users, Adelhelm can select from the most efficient coating methods combined with coating products from Chemours Company supplied through Intech Services.

The Adelhelm group continues to grow with the headquarters in Eningen, Germany, and satellite locations in Switzerland, U.S., Czech Republic, Poland, Romania, and India. Adelhelm LubriCoat NA is headed up by Adam Berres (left) and Dan Drayna (right). For more, visit their website.

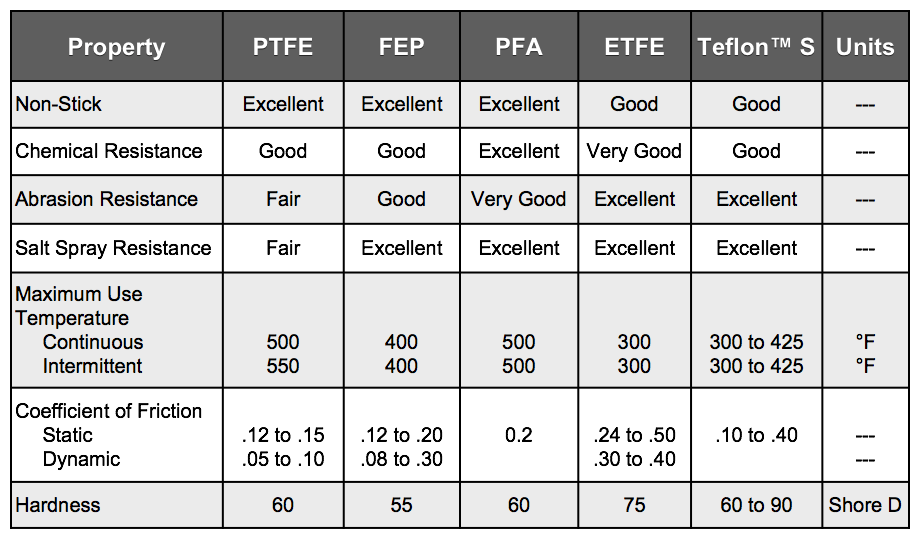

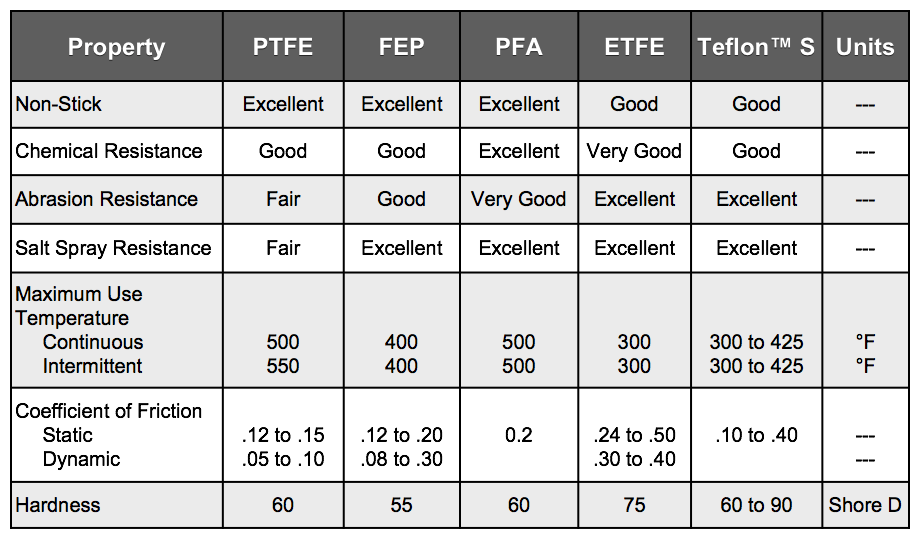

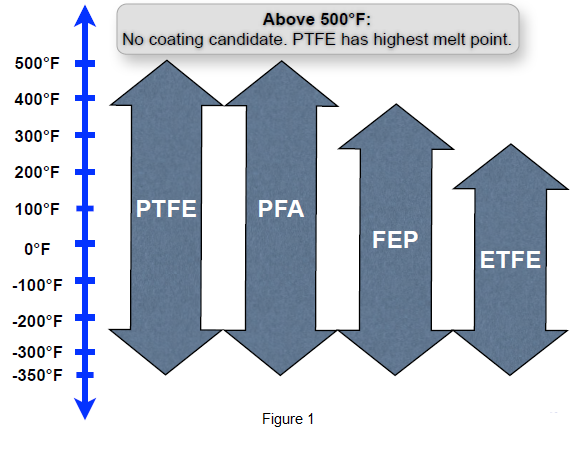

All Teflon™ coating varieties are “fluoropolymers,” which are fluorocarbon-based polymers with multiple carbon-fluorine bonds. This classification means that they possess a number of performance characteristics that are highly desirable in industrial and consumer applications. There are currently over 50 varieties of Teflon™ fluoropolymers that Intech Services provides.

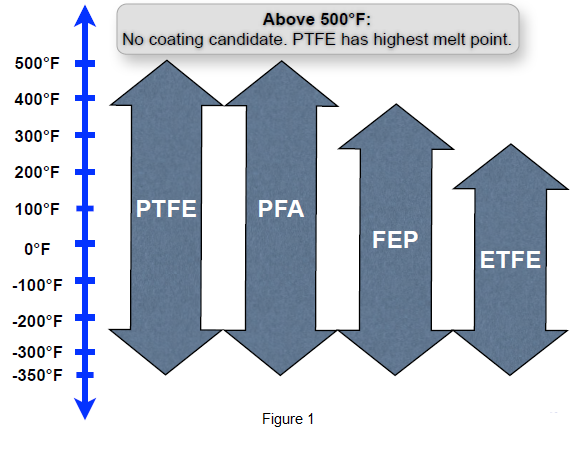

However, there are four main “families” of fluoropolymer chemical formulations. And within each product family, there are a number of Teflon™ products to provide you with the best industrial coating for your particular application. The four main families are:

PTFE: polytetrafluoroethylene

FEP: fluorinated ethylene propylene

PFA: perfluoroalkoxy

ETFE: ethylene tetrafluoroethylene

If you need help selecting the exact Teflon™ variety for your application, the Intech Services on-call Technical Support Team is always available to answer your questions: 302-366-8530. If you want to research every variety on your own, click here for Teflon™ SDS and Fact Sheets.

Teflon™ PTFE Coatings

PTFE nonstick coatings are two-coat (primer/topcoat) systems. These products have the highest operating temperature of any fluoropolymer (260°C/500°F), an extremely low coefficient of friction, good abrasion resistance, and good chemical resistance. Teflon™ PTFE is available only in water-based liquid form.

Teflon™ FEP Coatings

FEP nonstick coatings melt and flow during baking to provide nonporous films. These coatings provide excellent chemical resistance. In addition to low friction, Teflon™ FEP coatings have excellent nonstick coating properties. Maximum use temperature is 204°C/400°F. Teflon™ FEP coatings are available in water-based liquid and powder forms.

Teflon™ PFA Coatings

PFA nonstick coatings melt and flow during baking to provide nonporous films. Teflon™ PFA coatings offer the additional benefits of higher continuous use temperature (260°C/500°F), greater toughness than Teflon™ PTFE or Teflon™ FEP, and some Teflon™ PFA coatings can have film thicknesses of up to 1,000 micrometers (40 mils). This combination of properties makes Teflon™ PFA an excellent choice for a wide variety of uses, especially those involving chemical resistance. Teflon™ PFA protective coatings are available in both water-based liquid and powder forms.

Teflon™ ETFE Coatings

ETFE is a copolymer of ethylene and tetrafluoroethylene and is also sold under the Tefzel® trademark. Although not fully fluorinated, Tefzel® ETFE has excellent chemical resistance and can operate continuously at 149°C/300°F. This resin is the toughest of the fluoropolymer coatings and can be applied at film builds up to 2,000 micrometers (80 mils) to provide a highly durable protective coating. ETFE is available in powder form.

Intech Service Delivers Quality… Reliably

- Quality – 6 product lines that are the industry standard

- Flexibility – Over 50 Teflon™ varieties for catered solutions

- Accessibility – 24/7 e-commerce site for Teflon & supplies

- Availability – 98% of shipments ship same or next day

- Stability – 28 years supplying Teflon; thousands of satisfied customers

- Reliability – Our in-house experts know what you need

Intech Services President Mike Patterson introduces his Teflon™ industrial coating Technical Team, with over 50 years of combined Teflon™ coating experience.

Any Teflon™ industrial coating system is only as good as the prepared surface it is being applied to. Good adhesion can make or break the performance of a properly baked Teflon™ coating. The life of a coating can be directly related to the steps taken in cleaning and providing a good surface to adhere to. Find out the best substrates, proper surface preparation materials, and processes necessary to maximize adhesion results for Teflon™ coating systems in the “Application Overview” section of our website.

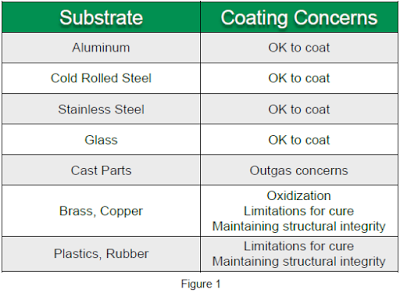

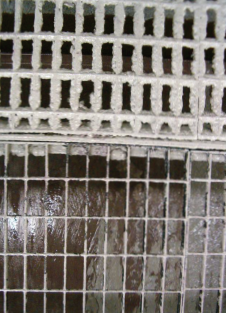

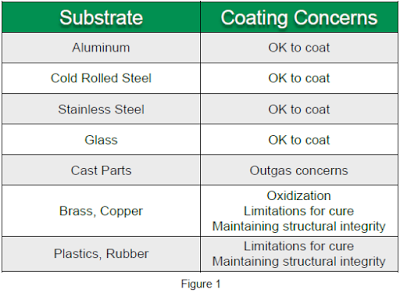

Substrate Considerations

Any substrate which is dimensionally and thermally stable at the bake temperature required for the particular product can be coated with Teflon™ Industrial coatings. Articles to be coated should be free of sharp corners and edges, excessive pits or porosity and excessive roughness as at welds and joints.

At bake temperatures greater than 450°F/232°C, certain metallic substrates are unacceptable. The melting points of tin (450°F/232°C) and lead (622°F/328°C) are too low to permit some Teflon™ bakes. The poor adhesion of copper to the copper oxide formed when copper is baked in air at high temperatures results in poor adhesion of the Teflon™ industrial coatings.

Because of reactivity at the high baking temperatures, Teflon™ coatings have relatively poor adhesion to magnesium and to aluminum/magnesium alloys containing more than 0.5% magnesium. Aluminum permanent-mold castings and die castings are successfully coated with Teflon™ coatings, but may show a high reject rate due to the formation of blisters caused by expansion of air bubbles in the metal during the high temperature bake.

Cleaning the Surface

In all cases, Teflon™ coatings should be applied over clean substrates. Normal industrial practices can be used, such as chemical washes or solvent cleaning and degreasing, but precautions must be taken to remove all residues from the cleaning process. Depending on the initial condition of the metal, it may be necessary to physically remove dirt, rust, mill scale, paint, etc. After cleaning, the metal should be handled with latex or nitrile gloves. Fingerprint and residual oil contamination may show up as a stain on the finish.

Preheating the Parts

Preheating metal substrates to the temperature of the Teflon™ bake is advantageous in removing traces of oil and other contaminants, especially when the metal is cast and somewhat porous. With most ferrous metal, this procedure has the advantage of temporarily passivating the surface against rusting and the blue oxide formed increases the adhesion of the acid primers. In the case of aluminum and stainless steel, these advantages are not apparent, and the preheating step can be omitted where clean metal is involved. Copper and brass should not be preheated in air because the resulting oxide has poor adhesion to the metal. A formic acid rinse reduces oxide formation to a degree on copper.

More on Grit Blasting and measuring surface profiles here.

Abrasive Media for Grit Blasting

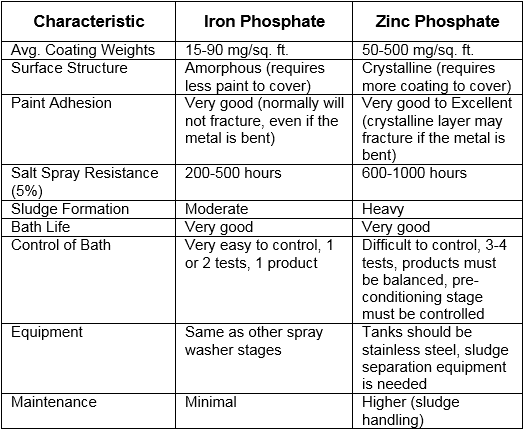

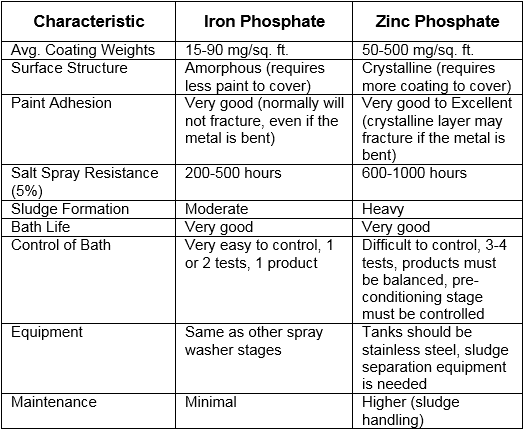

Conversion Coatings

Conversion coatings are the modified surfaces of metal resulting from specific chemical treatment. These conversion coatings, which can be on steel, aluminum, or most other metals, typically include zinc, manganese, and iron phosphates or chromates. The principle function of these coatings is to improve adhesion of finishes and maximize corrosion resistance. The functionality of conversion coatings depends upon their uniformity and the integrity of the coating, both before and after application of the final finish.

Preventing Rust

Since steel and iron rust rapidly after grit blasting, coatings should be applied immediately. Where delay is expected; or under conditions of high humidity, a solvent rinse with VM &P naphtha, or toluene containing 5% of kerosene may be employed. When the volatile solvent evaporates, a very thin film of kerosene remains to prevent rusting temporarily. While the presence of thin films of kerosene does not appear to affect the application of the 850-Line primers, the kerosene film may collect dust on long standing and require solvent washing before the finish is applied.

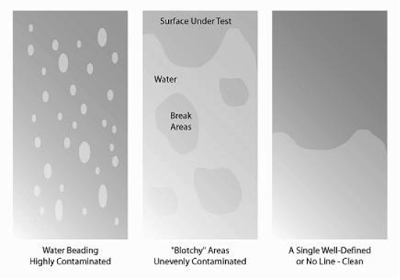

Testing Adhesion

There are several techniques for testing the bond strength between the coating and the metal surface. The most common test is a cross hatch test. Since this is a destructive test, it is typically performed on a test panel that is processed along with actual parts.

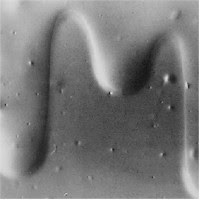

Common Problems Caused by Poor Surface Preparation

Air bubble pops: This is called outgassing, and can be prevented by preheating the part to 250°F before applying the coating.

Crater-like holes: These are called fisheyes, and can be caused by contaminants in the coating or on the substrate. This could even be grit from blasting that wasn’t totally removed. Make sure the spray area and substrate are completely contaminant-free before spraying.

Substrate adhesion failure: If the coating is coming off of the substrate, it could be because the blast profile is not deep enough or there are contaminants under the coating. Blast profiles of at least 2.5 microns are recommended, and profiles between 5.1 – 6.5 microns are frequently used. Always be careful to remove all of the blast media from the substrate before spraying. To make sure all grit has been removed, pre-bake the part at the coating’s cure temperature or higher.

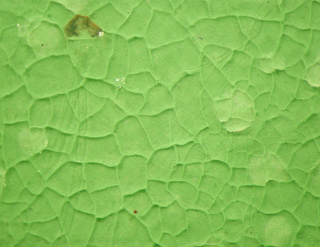

Mudcracking: Mudcracking is when the finished coating looks like the bottom of a dry, cracked pond. This can be caused by too severe grit blasting, wire brushing, or sanding that causes pits and scratches in the substrate’s surface. When sprayed, the coating will flow into the depressions, causing cracks in the cured coating.

There are over 50 varieties of Teflon™ industrial coatings, serving many uses in the current industrial marketplace. But deciding which one to choose for your particular application can be a challenge. Help us help you by preparing your answers to the following questions:

- What is the reason for coating?

- What is the substrate?

- What is the end-use service temperature?

- Will there be chemical exposure?

- Will the part come into contact with food?

- Are there any abrasion/durability concerns?

- What are the heat limitationsof the part?

- What are the part dimensions?

- What are the cost limitations?

- Can the part be removed?

- Have you tried another coating on the same part previously?

We’ve developed a downloadable worksheet to help you prepare for a call with our Technical Service Team.

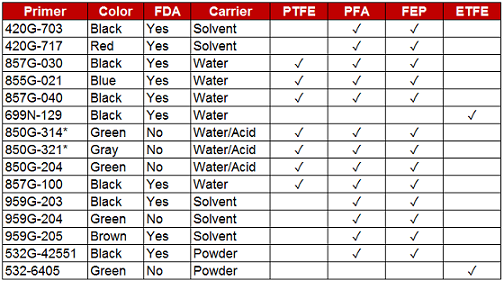

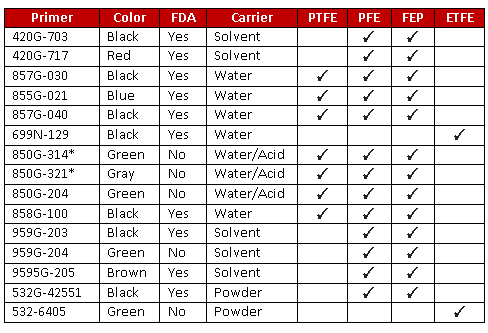

Here’s a Handy Teflon™ Coating Chart:

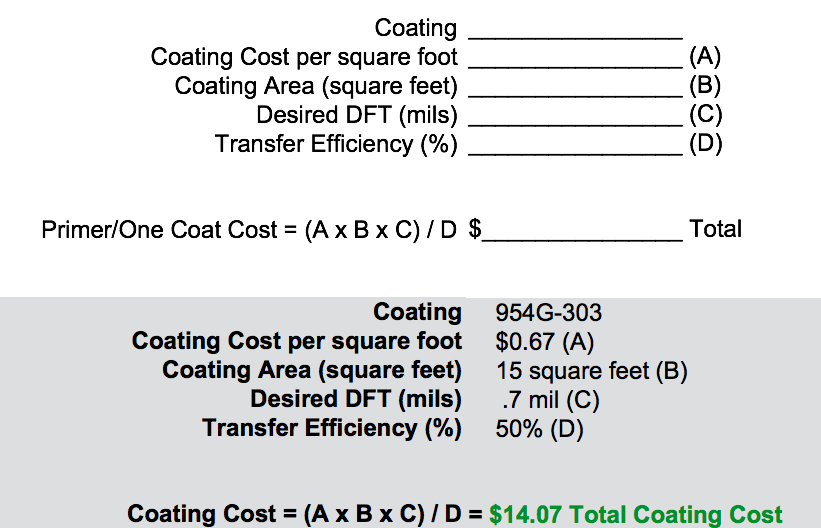

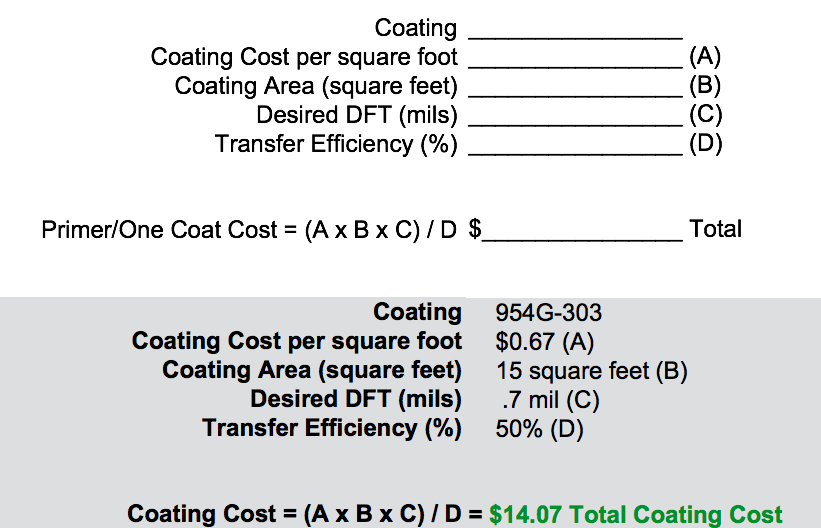

Calculating Teflon™ Coating Costs:

Additional Considerations When Comparing Coatings:

Film Thickness

Improved transfer efficiency

Extreme part cleaning

Extreme masking

Extended oven time (energy)

Complex part geometry, size, or weight

Special packaging requirement

Special inventory

Likelihood of rejects/rework

Rush delivery/maintaining inadequate stock

Money collection

Overtime

“Teflon™Coatings 2020” Kickoff Video! Join us on our journey to educate the coating community on Teflon™ coating application tips, troubleshooting, coating business strategies, Intech Insights—and much more. Catch them here or subscribe to our YouTube channel!

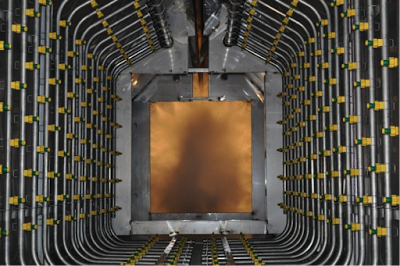

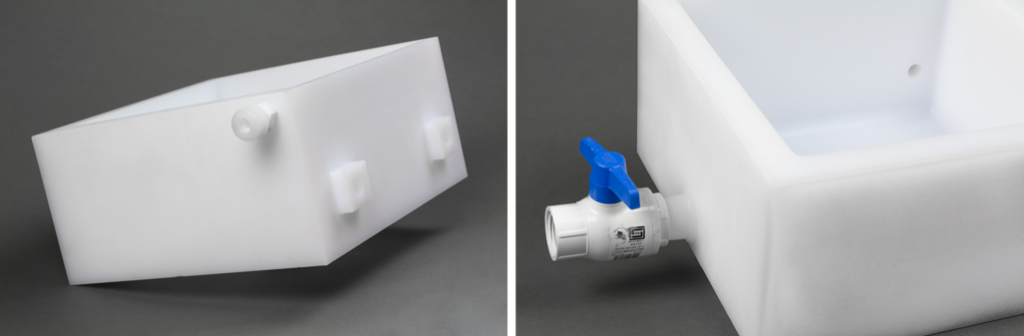

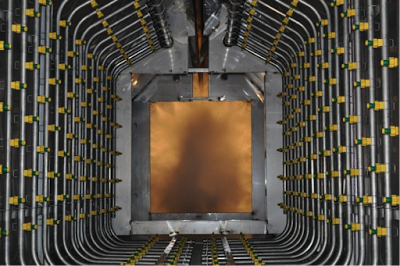

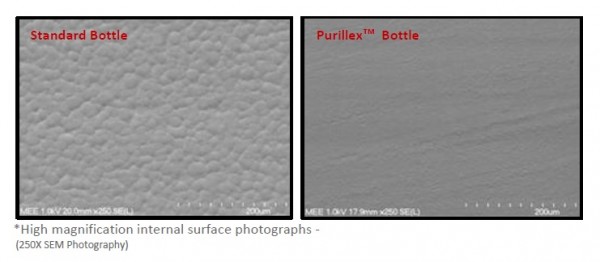

Semiconductor industry manufacturers use Teflon™ coatings to

prevent chip and component contamination from airborne particles. In “clean

rooms,” where often no personnel are even permitted, manufacturers coat

equipment parts with Teflon™ coatings to keep any extraneous particles from

entering the manufacturing process.

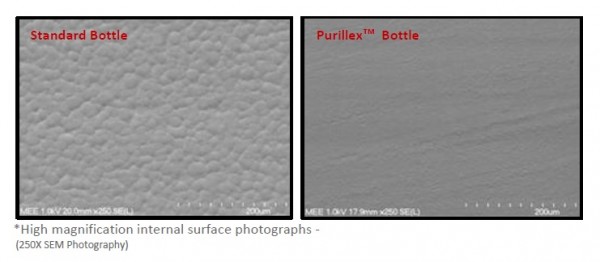

How Are Teflon™ Coatings High Purity?

The high purity and inertness properties of Teflon™ coatings have

several secondary benefits in clean rooms. Teflon™ coatings have superior

reliability, retention, and durability while also preventing contamination of

any kind. Another benefit is that Teflon™ coatings are easy to clean. This is due

to another Teflon™ coating property—“non-wetting.”

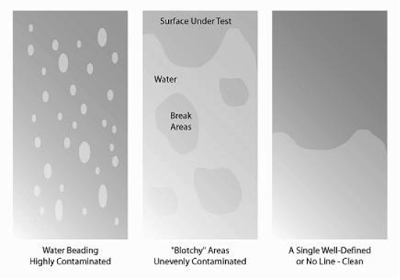

Non-wetting means that Teflon™ coatings are both hydrophobic and

oleophobic, making cleanup easier and more thorough. Hydrophobic substances

repel the polar ions in water and resist wetting. The low surface energy of the

coatings means that the cohesive forces in the water are strong enough to make

the water bead up and not spread across the surface of the coating. Oleophobic

means oil molecules are “repelled” from the surface. To be completely accurate,

molecules are not repelled, rather there is a complete lack of any attraction.

Teflon™ Coatings in Semiconductor Manufacturing

PFA

topcoats are also popular for semiconductor factory applications because

of their versatility, abrasion resistance, and purity. PFA topcoats are often used

for coat liquid tanks, liquid nozzles, and semiconductor wafer carriers. The

non-wetting property of Teflon™ coatings is especially important for coating

laboratory glassware, such as beakers and test tubes, in order to minimize

cross-contamination.

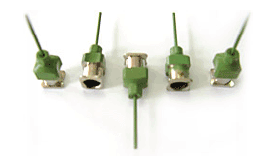

Teflon™ coatings also coat less critical semiconductor industry

parts, such as robotic armatures, for corrosion resistance. Popular one-coat

options include the FEP Epoxy

Liquid line that comes in green (954G-304) or black (954G-303). These

coatings resist chemicals and chemical vapors and can be easily cleaned.

Spray guns for Teflon™ coatings come in

a variety of shapes, sizes, and spraying technologies. The most

popular guns in Teflon™ coating shops are conventional spray guns, HVLP spray

guns, and Trans-tech spray guns. Here we look at the differences…

Conventional

spray guns use basic high pressure. The coating is blasted onto the

part at this high pressure using an air compressor. The high pressure finely

atomizes the spray giving the coating a very smooth finish. Transfer efficiency

for conventional spray guns is typically 50% or less.

High-volume

low-pressure (HVLP) spray guns increase transfer efficiency,

typically to about 65%. This means more of the coating actually makes it to the

part instead of being wasted. With HVLP guns, air is delivered at much higher

volume than conventional guns, but with a much lower pressure, so that more

finish ends up on the part instead of in the air. HVLP guns are compliant with

the California South Coast Air Quality Management District.

Trans-tech

spray guns use low volume, medium pressure. Transfer efficiencies are

normally about 60% or better. Trans-tech guns are the best of both worlds: the

finish quality is almost that of a conventional spray gun, with close to the

efficiency of an HVLP spray gun. Trans-Tech is used where compliance is not

required but cost savings is important.

Here’s a handy chart to help you choose:

Spray Gun Cleaning

To clean air caps: Remove the air cap from the gun,

place it in a clean solvent, and blow dry. If the small holes are clogged,

after soaking the cap in the solvent, use a toothpick or some other similar

soft implement to ream the holes. Never use wires or a nail because they can

damage the cap.

To clean pressure feed guns with an attached cup: Turn off the air

supply, loosen the cup cover and remove the fluid tube from the paint. Pull the

trigger while holding the gun over the paint cup to let the rest of the paint

drain back into the cup. Empty the cup and wash with a clean solvent and cloth,

then fill the cup halfway with clean solvent and spray it through the gun to

wash out the fluid passages. Make sure you spray into an approved, closed

container and that you follow local codes about disposing of solvents! Clean

the air cap and wipe the gun with a cloth soaked in solvent.

To clean pressure feed gun with a detached cup or tank: Turn off

the air supply and open the relief valve. Material in the hoses may be blown

back, so make sure the lid is loose and the gun is higher than the cup or tank!

Loosen the air cap and pull the trigger until all the material is back in the

cup or tank. A gun cleaner should be used to ensure proper cleaning. Place the

gun and cups over the nozzles in the cleaner and close the lid tightly. The

cleaner will spray solvent through the nozzles, keeping the solvent contained

so it can be disposed of properly. Be sure to dispose of the solvent correctly

according to local codes.

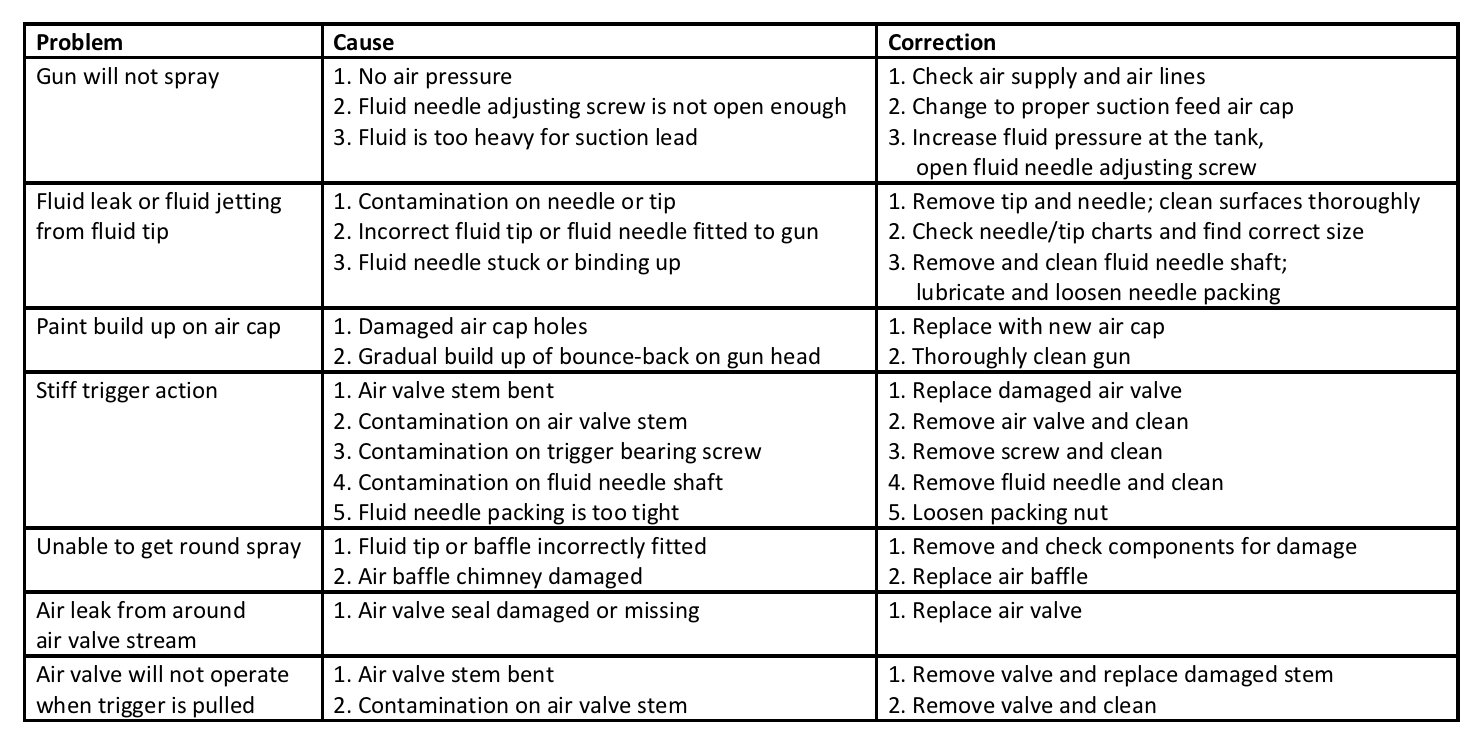

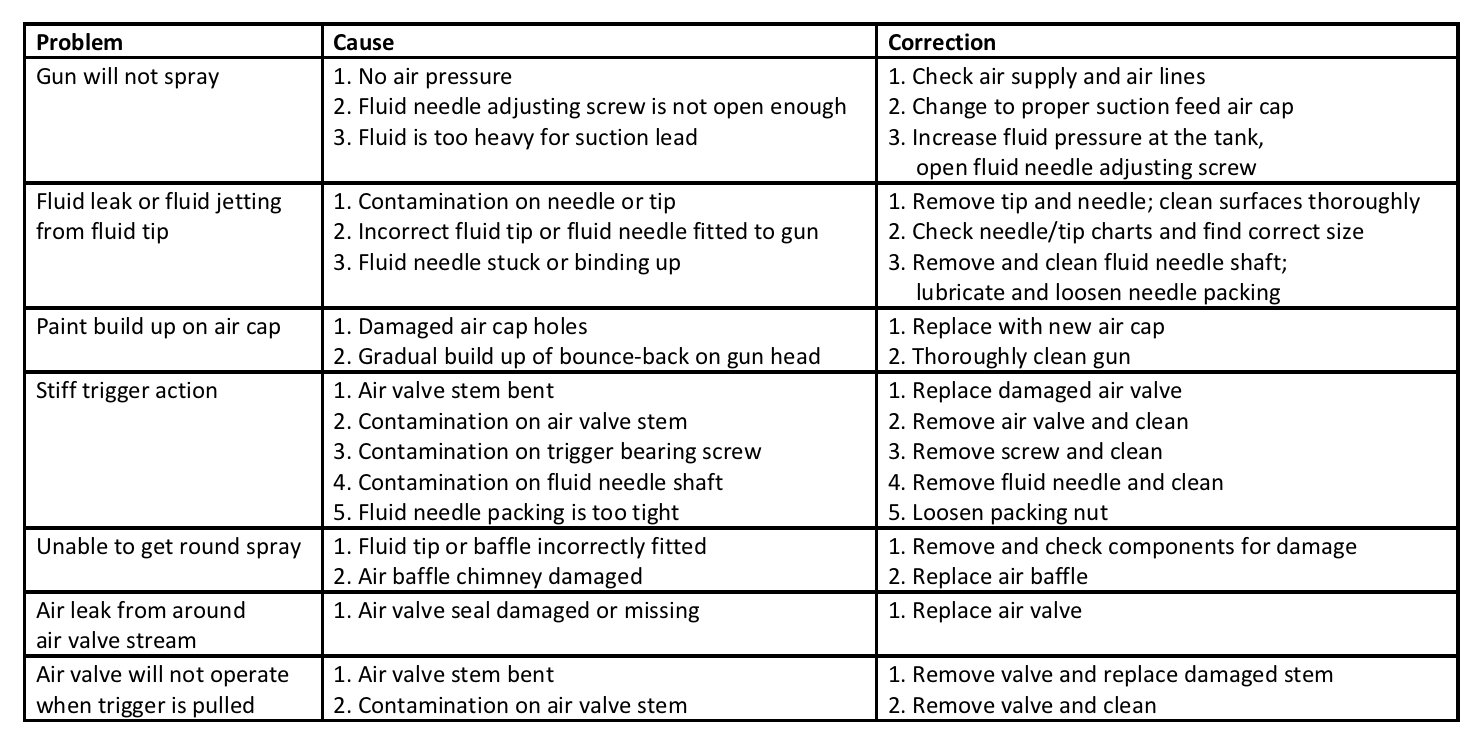

And here’s a handy Spray Gun Troubleshooting Guide:

https://fluorogistx.com/intech-insider-blog/troubleshooting-common-spray-gun-issues/

The flawless, repeatable release

properties of Teflon™ coatings

make them ideal for a number of

applications on packaging lines. Teflon™ coatings consistently convey goods and

packaging materials, seal plastic bags, and line glue pots, among many other

functions. These coatings cover the high-temperature bars that seal plastic

packages, as well as the glue pots that dispense glue for sealing.

Popular Teflon™ Systems for Packaging

The 3-Coat

Reinforced System (857G-040/-140/-240) is the preferred Teflon™

coating for packaging because of its high temperature rating, nonstick

properties, and industry-leading durability. Other applications on packaging

lines use

FEP Teflon™

S One Coats, and pure FEP and PFA topcoats.

The 3-Coat Improved Standard is the premium Teflon™ coating line

reinforced for scratch and durability. The line is for end-uses that require

non-stick, thermal stability to 500° F, and high lubricity. Decades of

innovation and technology have led to significant improvements in this coating.

This water-based, multi-color system is a unique blend of PTFE, PFA, and FEP

fluoropolymer chemistry. The three coats are Primer (855G-021), Midcoat

(857G-135 or -130), and Topcoat (857G-240).

These coatings are available in FDA-Compliant versions. It’s

always a good reminder to note that that there are

21 FDA-compliant Teflon™ coating

systems. According to the FDA

website: “It is the responsibility of the manufacturer of a Food Contact

Substance (FCS) to ensure that food contact materials comply with the

specifications and limitations in all applicable authorizations.” In the simplest

terms, FDA compliance means that any material that might contact food is inert

and safe for human consumption.

Here’s more on FDA Compliance:

https://fluorogistx.com/intech-insider-blog/what-does-fda-compliance-for-teflon-mean-/

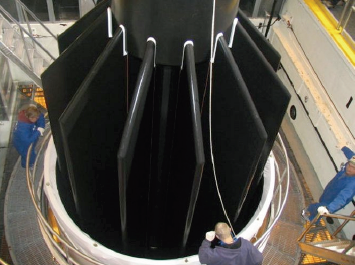

We congratulate Nordic Ware Industrial on becoming a Licensed Industrial

Applicator of Teflon™! Nordic Ware Industrial takes full advantage of FDA-compliant

Teflon™ products, coating thousands upon thousands of commercial and restaurant-grade

products out of its Minneapolis, MN, headquarters.

Over 40 years ago, the company began coating parts for industrial

applications to fill a market need for high-release properties. Since that time,

Nordic Ware Industrial has coated parts with a broad range of high-performance

coatings for applications ranging from appliances to space stations, for

customers located in places from the Arctic Circle to Central America.

Learn more on the Nordic

Ware Industrial Coating site.

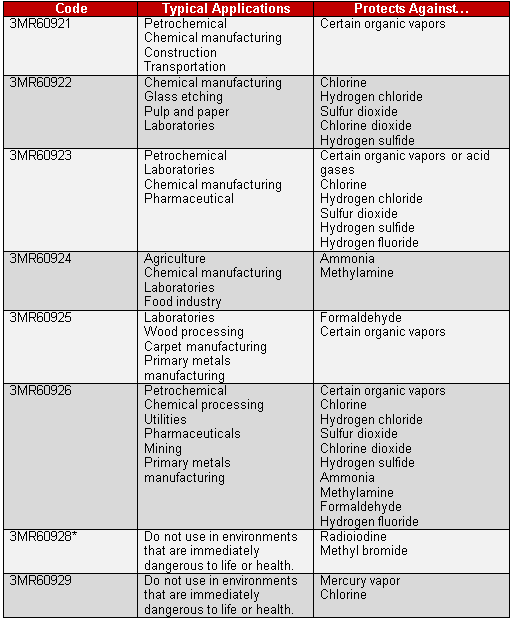

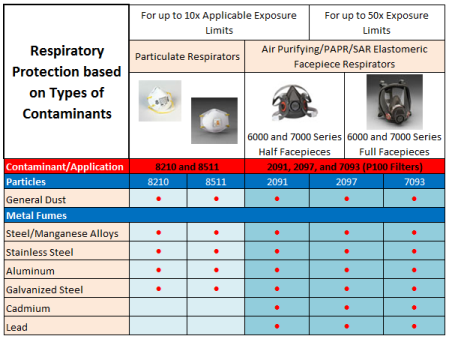

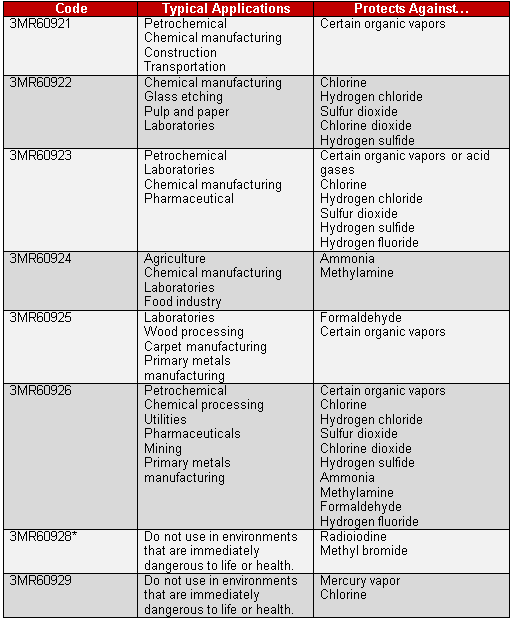

Choosing respirators, filters, and cartridges that fit your Teflon™

coating shop’s needs is very important because respirators come in many

shapes and sizes. You must make a decision between disposable

or reusable respirators, and you must make sure that the respirator is equipped

with the correct cartridge or filter for the respiratory hazards in your work

environment.

Both disposable and reusable respirators can be used to protect you from many harmful

substances. But it’s most critical to make sure you are using the right filter

or cartridge. For dusts, fumes, and mists, use a particulate filter, and for

gasses and vapors, use an appropriate chemical cartridge. Intech offers

all the Teflon™ supplies you need for coating Teflon™ in its online

Shop.

Particulate Filters

- Dusts: Created by sanding, dusting, or

sweeping some materials.

- Fumes: When metal is heated to its boiling

point, then cooled again quickly, there will be fumes.

- Mists: Little drops of a sprayed

material that stay in the air.

Chemical Cartridges

- Gases: Particles that diffuse freely to

fill the container or area they are in.

- Vapors: Created when liquids evaporate

(changing from a liquid state to a gaseous state) or solids sublimate (changing

from a solid state to a gaseous state, bypassing the liquid state all together).

Cartridge Care

A respirator cartridge starts working from the moment you open the

package it was shipped in, whether it is being used occasionally or constantly.

The environment in the facility will determine how long the wearer of the

cartridge is protected from the airborne toxins for which it was designed to

shield him or her from.

There are recommended procedures that management can use to evaluate the

environment, estimate cartridge expiration, and replace in time to assure the

coater’s safety. The cartridge wearer cannot determine when the cartridge

has expired because toxic air has no telltale taste or smell.

Disposable Respirators

Disposable

respirators usually only have particulate filters and are relatively

inexpensive. The benefits of disposable respirators are comfort, lightweight

composition, adjustable straps, and overall economy. Particulate

respirators will filter up to 10 times the applicable exposure limits only

for general dust, steel/manganese alloys, stainless steel, aluminum, and

galvanized steel. Do not use particulate respirators for cadmium or lead. Popular

disposable respirators are the 8210 model, which is

$16.99 for a box and the 8511

respirator, which is $24.99 a box.

Reusable Respirators

Reusable respirators can use either particulate filters or chemical

cartridges in half and full facepieces, but you can replace filters and cartridges

as they’re useful life expires. Filters and cartridges are available for many

applications, and many styles can be adapted to PAPR or Supplied Air Respirator

setups. Popular reusable respirators are the 3M 6000 series and 7000 series,

with cartridges that will filter up to 50 times the exposure limits for all the

contaminants listed below.

The Health Risks

The contaminants listed here have severe potential effects if you

are exposed to them:

- Steel/Manganese Alloys can cause

pneumoconiosis, siderosis, and central nervous system harm.

- Stainless Steel can cause pneumoconiosis,

kidney damage, lung irritation, and cancer.

- Aluminum can cause respiratory irritation.

- Galvanized Steel can cause metal fume

fever.

- Cadmium can cause metal fume fever,

respiratory irritation, kidney damage, and lung cancer.

- Lead can cause central nervous system

harm and systemic poisoning.

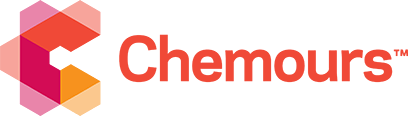

Of the eight Teflon™ coating properties, nonstick

and FDA-compliant may be the most familiar to consumers because of their use on

baking pans. But most consumers probably have no idea that that there

are

21

FDA-compliant Teflon™ coating systems

.

According the FDA

website

: “It is the responsibility of the manufacturer of

a Food Contact Substance (FCS) to ensure that food contact materials comply

with the specifications and limitations in all applicable authorizations. When

reviewing your composite formulations to determine compliance, consider each

authorization to be composed of three parts: the

identity of

the substance,

specifications including purity, or physical

properties and

limitations on the conditions of use.”

In the simplest terms, FDA compliance means that any material that

might contact food is inert and safe for human consumption. Teflon™-compliant

systems also offer temperature resistance, release, lubricity, and durability

for a multitude of applications such as baking molds, food production, food

assembly lines, and packaging lines. FDA-compliant Teflon™ coatings are

available in water and solvent based liquid formulations as well as powder.

Official FDA Regulations on Coatings

The Food and Drug Administration (FDA) Regulation

21.CFR

(and specifically Part 177) governs

components of coatings for direct food contact. Each category of the Teflon™

fluoropolymers has coating systems that, when applied correctly according to

Fact Sheet instructions, are FDA-compliant. (

Here’s a handy

printable list

.) When checking the Fact Sheet, check under

the “Food Contact” subhead to confirm FDA compliance.

One important thing to note is that when using a multiple coat

system, all the components (primer, mid-coat, topcoat) must be FDA-compliant in

order for the system to be FDA-compliant. And if your coating is

FDA-compliant, it is also technically USDA-compliant, but the USDA requires a

special letter from the applicator.

For more information on the USDA compliance process, contact the Intech

Services technical team at

302-366-8530.

Polyurethane foams are used in construction for insulation, sound

absorption, various types of padding, and structural reinforcement. Outside of

construction, polyurethane foam is an integral part of household appliances,

automobiles, packaging, and footwear. The Teflon™

coating properties that allow for excellent release are

non-stick, low coefficient of friction, ease of cleaning, and FDA compliance.

Polyurethane Molds

The polyurethane

molding industry has long relied on manually applied release

agents on their metal molds for rubber or plastic components during the

manufacturing process. The procedure of applying these release agents is both time-consuming

and expensive. Teflon™ coatings are now offering long-term solutions that

completely replace release agents for a variety of the products used in polyurethane

molding.

When maintained properly with regular cleaning, Teflon™ coatings

can perform through thousands of molding cycles. Removing release agents offers

significant benefits to polyurethane foam manufacturers in the form of enhanced

compliance with environmental regulation, improved safety conditions for

employees, reductions in product defects, and the complete elimination of dry

ice blasting.

Polyurethane Processing

Teflon™ coatings are also now being used to coat polyurethane mixing

blades for easy cleaning and extended service life of the blades. Hardened

foam quickly builds up on the steel mixing blades, and the processes for

removing it can be very time-consuming and labor-intensive. One case

study saw polyurethane foam production increase dramatically. By

cleaning quickly between mixes with methylene chloride and paper towels, the

company was able to accomplish up to 13 mixes in a single day.

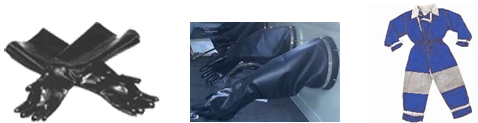

When

coating services employees’ hands are in contact with hazards, employers must

require the proper hand protection to be worn. To figure out which kind of

glove works best for hazardous environments such as surface blasting and

Teflon™ coating, coating services companies must evaluate the gloves’

protection requirements relative to the tasks being performed, and consult

industry standards for safety.

The

Occupational Safety and Health Administration, or OSHA, has the general

requirements for selecting appropriate gloves (Standard

1910.138 – Hand Protection). This standard covers protection selection requirements when

hands areexposed to

hazards such as those from skin absorption of harmful substances, severe cuts

or lacerations, severe abrasions, punctures, chemical burns, thermal burns, and

harmful temperature extremes.

The

American National Standard for Hand

Protection Classification is another guide for selecting appropriate gloves. The document

gives test methods

and classification levels for many glove characteristics. It also has pass/fail criteria

for hazardous exposures, such as chemical permeation, detection of holes, and

heat and flame resistance. Here we review common high-temperature gloves that

should be part of your Teflon™ coating supplies, and the

basics of sizing and maintenance.

Gloves

that Take the Heat

For

applications where high heat protection is the top priority, Kevlar®

gloves

are often the answer. The looped construction of Kevlar traps air, making these

gloves excellent insulators. The fabric also gives greater durability and cut

resistance than regular string knit work gloves. Other high-temperature

gloves

include reversible mitts, Flextra® unlined heat resistant gloves, and heavy

duty olive drab flame retardant knit wrist gloves.

Gloves

with Permeation Resistance

Butyl gloves have the highest permeation

resistance to gases and water vapors of any other glove material. They offer

excellent resistance to methyl isobutyl ketone and methyl pyrrolidone, found in

thinners TN-8595 and TN-8718. Blasting gloves protect hands and arms from high

pressure particles, and welders gloves include options such as reflective

aluminized leather back wool-lined gloves.

Glove

Maintenance

Regular

glove maintenance is important in ensuring employee hand protection. Proper

care can also save you money by extending the life of each pair. Proper glove

maintenance focuses on three main areas: cleaning, inspection, and storage. Each

pair should be inspected for damages on both the inside and outside prior to

use, and all gloves should be kept in well ventilated containers away from

direct sunlight.

Glove

Sizing and Cuff Types

When

choosing gloves for workplace safety, two key factors that should always be

considered are glove size and cuff style. Choosing appropriately sized gloves

is as simple as measuring the circumference of your hand just below the

knuckles.

- XSmall: 6” to 7”

Hand Circumference

- Small: 7” to 8”

Hand Circumference

- Medium: 8” to 9”

Hand Circumference

- Large: 9” to 10”

Hand Circumference

- XLarge: 10” to 11”

Hand Circumference

Cuff

Listing Terms

- Knitwrist: Prevents debris from entering the

glove, keeps cold air out and warmth in, fits under clothing sleeves

- Slip On: No cuff, easy to put on and off,

primary use for general purpose applications

- Safety Cuff: Length varies from 2.5″ –

2.75″, gives added protection to forearms

- Rolled beaded Cuff: Increased

strength and protection from chemical droplets

- Gauntlet Cuff: Typically

4.5″ or longer, greater upper wrist protection

- Serrated Cuff: Better

gripping on surface edge for easier glove removal

- Band Top: Allows air circulation, light wrist

protection

- Straight Cuff: Addition

length to protect from chemical runoff

Release agents comprise any substance that helps a container

“release” whatever it is holding easily and without residue sticking to the container.

The most common release agents are oils that keep surfaces slippery and

“non-stick.” Of course, oils can be messy, costly, and a safety risk. A variety

of chemical formulations are also used, but all have similar drawbacks.

Teflon™ coatings remove release agents from the equation by

providing the same release performance in a more permanent way. The Teflon™coating properties that allow for excellent release are non-stick,

low coefficient of friction, ease of cleaning, and FDA compliance. The most

common places where Teflon™ coatings successfully and economically replace release

agents are in the molding industry.

Industrial Plastic Parts Molding

Teflon™ coatings cut manufacturing costs by eliminating release

agents and reducing product defects. Teflon™ coatings provide a more permanent,

nonstick, repeatable high-release solution for processes across every molding

industry segment. Popular

Teflon™ coating lines for molding include FEP, FEP Teflon

S

one-coats, and PFA coatings for

higher operating temperatures.

Medical Device Parts Molding

The majority of the medical industry molding market is represented

by the makers of medical instruments, pharmaceutical processing, and packaging.

Applications where Teflon™ coatings can replace release agents are in the

manufacturing of medical waste trays, surgical handles, forming mandrels, pill

molds, gel cap molds, centrifuge baskets, lab equipment, and dental molds.

Packaging applications include material handling, blister pack forming, and heat

sealing.

Molding Industry Resource

The Society of Plastics Engineers (SPE) unites

plastics professionals worldwide, helping them succeed and strengthening their

skills through networking, events, training, and knowledge sharing. The SPE’s ANTEC®

2020 conference is the largest, most respected and well-known technical

conference in the plastics industry. The next conference is March 30 to April

2, 2020, in San Antonio.

Polyurethane Molding

For more specific details on the Polyurethane Molding industry, read this blog post.

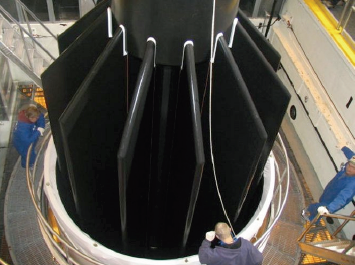

All products and parts used in the

aerospace industry have to be proven safe through rigorous testing and high

production standards. Aerospace parts from small fasteners to wire insulations

to fluid gaskets must stand up to demanding operating conditions for extended

periods of time.

Teflon™ coatings used in the aerospace

industry are highly specified, highly qualified, and resistant to a wide range

of stresses. They offer durability and toughness for an industry with unique

needs. Here we’ll review Teflon™ product lines commonly used in aerospace as

well as pertinent SAE standards and aerospace standards resources.

Teflon™

for Aerospace

The combination of many Teflon™ coating

properties make these coatings particularly robust for aerospace. Teflon™ PTFE and

FEP coating systems are among the most popular in the industry.

PTFE 851G-2XX and 852G-2XX are ideal systems for aerospace applications

requiring thermal stability and superior coefficient of friction. The acid primers

850G-204 and 850G-314 offer high

lubricity in a thin film. Acid primers are usually used under a PTFE Topcoat,

but the acid primer alone is useful in some applications such as fuel filter

screens.

FEP One Coats (954G-3XX and

959G-2XX) are also well-suited for aerospace because of their durability and

high service temperatures of up to 425° F. And the FEP system of 953G-506 (primer) and 953G-401 topcoat provides premium release

properties with good chemical resistance. Toilet bowls on airplanes are often

coated with this FEP system so the toilets use less water, planes carry less

water, and planes use less fuel.

Call Intech Services for more technical

details at 302-366-8530.

Common SAE

Standards:

- AMS2515H PTFE

Resin Coating, Low Build, 370 to 400 °C (698 to 752 °F) Fusion – This

specification establishes the engineering requirements for producing thin

coatings of PTFE (with acid primer) on parts and the properties of such

coatings.

- AS 9100D Quality

Management Systems – Requirements for Aviation, Space, and Defense

Organizations – This standard includes ISO

9001:2015 quality management system requirements and specifies additional

aviation, space, and defense industry requirements, definitions, and notes.

- AS12500 Corrosion

Prevention and Deterioration Control in Electronic Components and Assemblies – This

specification covers corrosion prevention and mitigation aspects in Avionics,

Electronics, and Electrical Wire Interconnect Systems. (Replaced MIL-HDBK-1250.)

- AS7489 Standard

Requirements for Aerospace Organic Coatings Applicator Certification – This

standard establishes the minimum requirements for training, examination, and

certification of aerospace coatings application personnel applying liquid

organic coatings to interior structural or exterior substrates.

Aerospace Coating Resources:

- Aerospace

Industries Association–The National

Aerospace Standards (NAS) are voluntary standards developed by the aerospace industry.

- Aerospace Standards Overview by ASTM – Compiled by

a number of ASTM International committees covering aircraft construction and

parts manufacturing.

- The Gardner-Sward Handbook – This “Paint

and Coating Testing Manual” is a valuable guide to standards of many national

and international organizations.

- IAQG-OASIS

Database – The Online Aerospace Supplier Information System (IAQG-OASIS) is a

reliable source for aerospace supplier certification and registration data.

- Nadcap

– Nadcap is the leading worldwide cooperative program

of major companies designed to manage a cost-effective consensus approach to

special processes and products and provide continual improvement within the

aerospace and defense industries. And here’s an FAQ Page on Nadcap

Accreditation by Boeing.

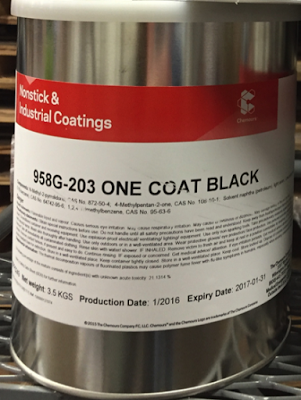

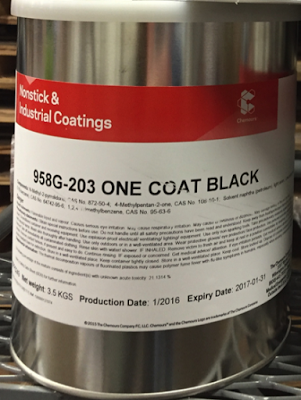

One common manufacturer’s specification

not listed is the Boeing BMS10-146 material specification, which outlines

application and performance requirements of Teflon™ 958G-203 One-Coat. This is not a

public standard, but one you should be aware of nonetheless.

Of the many quality

assurance tools that a coating services supplier should have on hand, coating

thickness gauges are one of the most important for maintaining

high-quality coatings that both perform properly and meet external standards.

Another substantial benefit is cost savings, as keeping coatings consistently within

specifications can reduce material and labor waste. And you should consider

whether the time savings of a tester

that measures continuously at 140 times per minute is worth the investment

to prove your coatings are consistent.

Coating thickness gauges (aka paint meters or mil gauges) are used

to measure dry film thickness without leaving marks on your parts. These are a “non-destructive

testers” with great repeatability in measurements. Dry film thickness is

probably the most critical measurement in the coatings industry because every

coating has thickness range specifications. A coating thickness gauge provides

vital information that can confirm the expected life of the substrate, the

coating properties’ performance, the coating appearance, customer expectations,

and the job’s compliance with international standards.

Managing

Coating Expectations

Many jobs in the Military and Aerospace segments require

verification of the work that you are performing. Suitable coating thickness gauges

are certified by the all the applicable ASTM Standard test methodologies, which

allows you to compete in markets that are sensitive to these specifications. Thickness

testers can also compile the measurements you take and deliver a formal report

that can be shared with the end user.

Most quality shops lay out pass/fail expectations of their customers before

accepting their order, and more end users these days are requiring proof of

testing. Coating thickness gauges demonstrate to your customers that the

coatings were applied to the thickness they requested. This will help you

eliminate rejects and take your customer satisfaction to new levels.

Incorporating thickness measurement into your everyday processes also

saves on material costs. Monitoring coating thickness will drive your coaters

to better control thickness and eliminate excessive wasted coating. As an

example, if you purchase $10,000 in coatings a year and improve your thickness

control by .5 mils, you would save $2,552 a year.

Save Money with Better Technique

By using these simple techniques, you’ll be able to cut out the

waste as well as achieve a better, more consistent finish for your Teflon™

industrial coatings.

- Plan of Attack: Have a plan before pulling the trigger. Plan to attack trouble

spots and difficult to reach areas first.

- Spray

Distance: The spray distance is based on the spray equipment,

coating, complexity of the part, and spray environment. By keeping the gun at

the same distance from the part the entire time you’re spraying, you can

improve the consistency of the film thickness over the whole part. Increasing

the gun distance increases the pattern fan size, and the coating thickness

decreases as it is distributed over a larger area.

- Gun Angle: Maintain

controlled gun angle to the part. Yaw and pitch spray angles will result in a

non-uniform spray pattern distribution, causing inconsistent film thicknesses.

- Spray Pass

Overlap: Each spray pass should overlap 50% to 75% of the previous

pass. Overlapping below 50% results in “striping,” or variations in the film

thickness. The more you increase the overlap, the thicker the coating, so

overlapping above 75% requires more spray passes and more coating.

- Spray Pass

Speed: Adjust the spray gun speed to achieve consistent films.

Before pulling the trigger, consider the coating flow rate and the target wet

film thickness. Adjust the equipment before spraying to find a flow rate that

lets the applicator move at a controllable, comfortable speed. Spraying too

fast can lead to decreased film thickness, and sometimes extra coats will be

needed to make up the deficit.

- Trigger

Control: Maintaining a consistent trigger pull on each spray pass directly

impacts the flow rate, spray pattern size, and transfer efficiency. Start

triggering immediately before the lead edge of the part and release the trigger

immediately following the lag edge. Fully pulling the trigger provides constant

flow rate control. The fluid knob on your spray gun can be adjusted to restrict

the trigger travel distance so you can always pull the trigger all the way.

Partial triggering, however, can be very useful for blending and touching up.

- Edge

Banding: Partially pull the trigger to spray a light coat around the

edges of the part. Then spray the center of the part, blending the edges into

the first coat. Banding can increase transfer efficiency and increase film

thickness on the edges. This technique ensures the edges get coated completely

while maintaining consistent film thicknesses.

If you’re looking for more tips on keeping your Teflon™ coating

services at the highest quality consistently, read our other blogs on “Basic Quality

Testing” and “Advanced Quality

Testing.”

We usually list the total number of Teflon™

coating properties at eight. The Dry Lubrication property also goes by

“Lubricity” and “Low Coefficient of Friction.” To the layman, this Teflon™

property might sound a lot like “non-stick,” but there is a significant

functional difference.

Non-stick means that almost no solid substance will adhere to the

surface. Dry Lubrication, on the other hand, refers to how easily a coated

surface will slide over another surface. The most common Teflon™ coatings used

for high lubricity in industrial applications are PTFE

one-coats in the 958G line (-303, -313, -404, and -414).

Dry Lubrication and Friction

Friction is the force created when two objects rub together and

motion is hindered. With a Teflon™ industrial coating, the “coefficient

of friction” is generally lowered to a range of 0.05 to 0.20, depending on

the load, sliding speed, and type of coating used. Dry Lubrication is very

important in any application that has moving parts touching each other

frequently or with significant force.

Teflon™ PTFE one-coats are superior dry film lubricants with

smooth and slick finishes fusing to substrates with strong adhesion to provide

great durability. These industrial coatings are excellent for minimizing

friction and galling, as well as preventing seizing, especially where

re-lubrication with fluid is not possible or there is exposure to dirt or dust.

PTFE one-coats are often used in the automotive, aerospace, and oil & gas industries

because of the ideal combination of Teflon™ properties available under different

grades of durability and thickness.

958G Teflon™ Coating Properties

The popular 958G PTFE

line provides high heat resistance to operating temperatures of

up to 500 degrees F. These solvent-based coatings are also easy to apply for a

number of reasons. They apply in one coat, cure schedules can be flexible, they

have superior adhesion, and cleanup is painless.

The thin-film 958G-303 version is an industry standard and has

been used for dry lubrication for many years. The 958G-313 version, introduced

in 2016, is also a good option because it is more durable than -303. For

thicker film applications (up to 4 mils DFT) with high lubricity, we recommend

using 958G-406 (black) or -414 (dark green).

A “Make-or-Buy” decision is when you wonder if you’ll save money

by fabricating parts in-house instead of purchasing them pre-made from a supplier.