This summer Intech Services will provide a series of blogs dedicated to the Teflon® coating selection process. In order to select the right product for your coating job, there are three important areas that need to be understood:

Within each of these areas are vital questions that need to be answered to ensure the most effective coating for the job at hand.

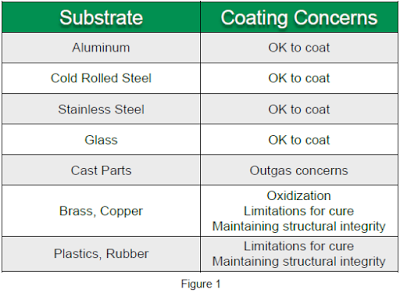

The second in the summer series will focus on Understanding the Part.

Understanding The Part:

For additional resources on the coating selection process please contact us directly at 302-366-8530, refer to the Compass Corrosion Guide, or refer to our Comparative Property Chart.