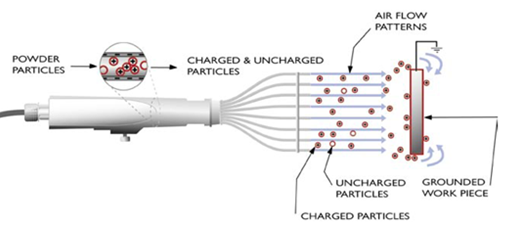

Tribomatic static charging is the second most common method of spraying powder coatings, after corona charging. The powder develops a charge while passing through special hoses and guns. As powder contacts these non-conductive surfaces, friction causes the particles to lose electrons. These particles then develop a powerful positive charge. No high voltage or lines of force are used which allows for easier penetration of deep recesses. Tribomatic charging is efficient in developing a static charge within the powder, however, coatings must be specifically formulated for this system.

Advantages:

Disadvantages:

For more information about Tribomatic static charging, read TCI’s Troubleshooting Guide.