This series is intended to highlight the long-standing careers of devoted Chemours™ Teflon® coaters and their accomplishments in the industrial coating field. These pioneers in the Teflon® coating industry are early adopters of the coating and have helped to shape the way Teflon® has grown and evolved as a reputable industrial fluoropolymer. With the pioneers’ vision and ingenuity, Teflon® coating continues to be regarded as the elite fluoropolymer of choice.

Our interview series continues with a spotlight on Mark Tate of Sun Coating Company. Located in Plymouth, MI, Sun Coating Company has been applying DuPont™ Teflon® industrial coatings since the 1960’s. They specialize in applying technologically advanced coatings to enhance and improve the properties for release, nonstick, low friction, abrasion-, wear-, and corrosion-resistance, dry-film lubrication, galling, noise reduction, high temperature, and FDA-compliance. Mark generously took some time to speak with us and share some of his successes, challenges, and views on the future of the industrial coating industry.

Q: When was your company founded?

A: Sun Coating was founded in 1962.

Q: Who founded the company and why?

A: My father, Joe Tate Jr. founded the company. While he was working for a well-known company in the plastics industry, Teflon® coating was being used as the “in-house” coating. Joe was asked to find a local coating source. As a result, he saw a need for coating source and started Sun Coating.

Q: What was the first significant piece of equipment you purchased?

A:Most of the early significant equipment was related to the automotive sector. Sun was a big player in the automotive sector, producing high volume coating of automotive parts, including throttle bodies, pistons, seating components and steering mechanisms.

Q: How would you describe the changes in the company now from when it was first started?

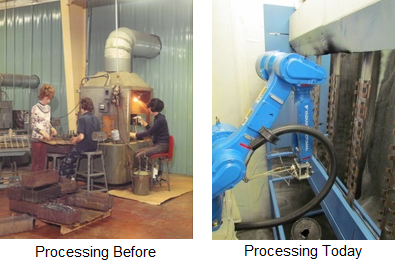

A:Sun Coating started as a garage/job shop, which then grew into the large facility it is today. We went from batch processing and simple spray equipment to automated robotics. We pushed the envelope over the years and developed and invested in some unique application techniques.

Q: What would you consider significant milestones in your company?

A:

Q: How has the coating industry itself changed over time?

A:The coating industry is now a world market, including Europe, Mexico, Puerto Rico, and India. The actual selling of coatings has changed as well. Today you need to do more than just go knocking door to door. Customers want information fast; the website is an aid in communicating, educating and developing the application. These technological interactions have made the world more accessible for us. Our Automotive Customers are worldwide.

“Fifty years ago, we were driving down to Dearborn to do these things. Now an international conference call is the norm.”

Doing business today on a worldwide scale can be demanding and challenging. Some of the obstacles we face include language barriers and scheduling conflicts around varying international holidays that effect production.

Q: When did you get your LIA license from DuPont?

A: We have a plaque from DuPont dated 1968.

Q: How has being an LIA affected your company?

A: Overall, the LIA status has given Sun credibility as an industrial coater. We are able to post our LIA status on our website which lets customers know we are in great standing with DuPont. The LIA status is a good marketing tool for us as well. It shows that DuPont takes pride in the company’s they do business with. We as coaters must uphold a certain standard to remain an LIA and that offers our customers reassurance with our ability. The marketing and advertising benefits of an LIA status are something we hope to utilize more of in the future.

“I’ve had a great relationship over the years with DuPont.”

Over the years Mike [Patterson], along with Intech, has done a tremendous job supporting Sun Coating. Intech provides timely delivery of material. Communicating and ordering is easy with their unique Intech Marketplace. We have come to rely highly on our supplier for coatings as well as leads. Intech and Sun Coating are good partners in meeting the challenges of the industry as well as growing the business and its value. Mike and his team do a tremendous job making it easy for Sun Coating to do business.

Q: What is your favorite DuPont coating?

A: “The one that brings me the next job.”

All of DuPont’s products are of the highest quality. They offer a broad variety of coatings and all the coatings are user friendly. We use many coatings in all our different sectors and markets. Without the options and variety we would not be able to accomplish all that we have as a company. We are confident that we are providing our customers a quality product with DuPont ™ Teflon® industrial coatings.

Q: What excites you about the future of the coating industry?

A: This is a tough question because we don’t know what tomorrow brings. In the world platform, business is always changing. However, we are always looking to develop new opportunities for Sun Coating’s services to be used. Whether it is finding new coatings that work and perform better for our existing customers or new customers, Sun Coating is on the forefront of the industry.