The “Faraday cage effect” occurs when the inner recesses and corners of a charged substrate do not have a charge, and the charged powder particles create resistance, making it difficult to coat these areas. There are ways to overcome the Faraday cage effect and better coat inner corners and odd part geometries.

Overcoming the obstacles of the electrostatic process:

These methods can use excess powder, have higher film thicknesses than desired, and could result in an uneven film build.

Using the electrostatic process:

These methods could result in a slower application time.

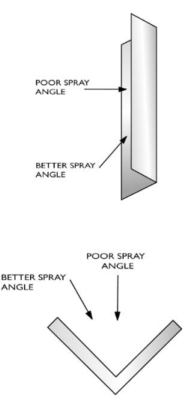

Spraying in the Faraday Cage: spraying at the recesses of a part at an obtuse angle can help to apply the coating properly.

For more information about how to overcome the Faraday cage effect, read TCI’sTroubleshooting Guide.