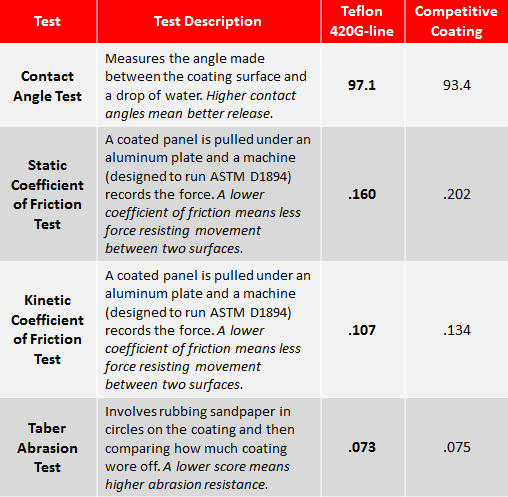

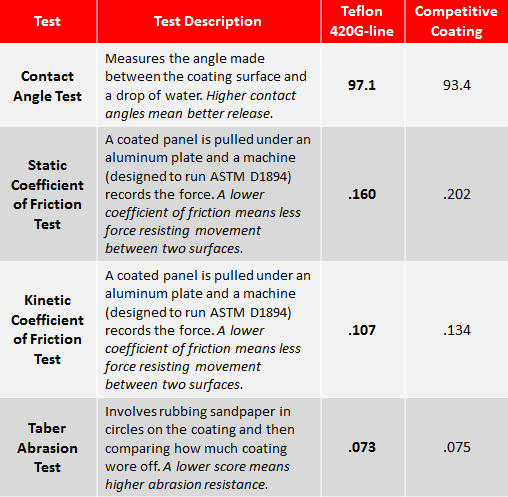

The DuPont™ Teflon® 420G-line is used primarily in the food processing industry because of its excellent release qualities. Compared to a competitor’s FDA-conforming one-coat, the DuPont™ Teflon® 420G-line has several competitive advantages over the other coating, including better release, a lower coefficient of friction, and higher abrasion resistance. The following test results show that Teflon® 420G coatings are superior to the competition and are a long-lasting coating solution in the food processing industry.

Teflon® Coatings’ Superior Performance Qualities:

- Stratification: DuPont™ Teflon® industrial coatings stratify while curing, which means the fluoropolymer rises to the top of the coating and the resin stays on the bottom close to the substrate. Stratification results in better release qualities from the fluoropolymer on the top and higher durability from the resin on the bottom. The competition’s coating does not stratify.

- Chemistry: Reverse engineering of the coatings found that Teflon® coatings contain PTFE and PES resin, while the competitive coating contains PTFE, FEP, and PES resin.

- Fluoropolymer Ratio: Teflon® coatings have a higher ratio of fluoropolymer to resin than the competition, which means there is more fluoropolymer in the coating.

- Property Comparison: The 420G-line has better release, a lower coefficient of friction, and showed a higher resistance to wear and abrasion than the competitor’s one-coat.

Introducing an FDA One-Coat Competitive Analysis Marketing Piece:

We have created a marketing piece for you to utilize in your sales efforts with customers. You can download a copy of this marketing piece here. If you would like to see the full testing data, please contact Intech to request the data sheet.