Hitting the Target of a Firearm Finish

You may have heard that the custom firearm industry has been using Teflon™ finishes on several types of gun and rifle parts. Why is Teflon™ the most effective and long lasting choice?

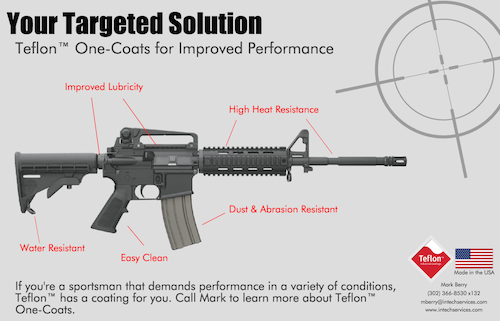

Teflon™ provides dry film lubricity, thermal stability, durability, chemical and corrosion resistance, easy cleaning and a matte finish.

Teflon™ is used as a dry film alternative for wet lubricants on interior, moving components, such as bolts, trigger assemblies, magazines, sliding rifle stocks, and bipods. All of these parts normally require repetitive maintenance (causing gun owners to spend added time and money). Many times, wet lubricants such as oil cause residual dirt to build up, resulting in the need for routine cleaning or the use of harsh chemical cleaners that can be damaging to finishes or firearm parts.

One finish often used on gun parts is ceramic paint, which lacks lubricity and is not specifically made for tight tolerances. Teflon™ coatings offer unsurpassed lubricity in comparison to ceramic coatings. Additionally, Teflon™ coatings’ thin film application ability is the perfect fit for tight tolerances.

Metal treatments and plating processes are also known to harden and protect metals from corrosion. Yet, what these treatments provide in corrosion resistance, they, too, lack in lubricity.

Teflon™ finishes offer a wide range of solutions to the firearm industry where other coatings fall short. This American made finish can give firearm owners the outstanding qualities they are looking for in order to enhance and protect their investment.

For more information, visit our website here. If you would like to learn more or discuss how this solution could work for you, contact Mark Berry, our General Market Segment Leader.