The first truly water-based, low VOC, and easy-to-use coating offering outstanding corrosion resistance of up to 3,000 salt spray hours.

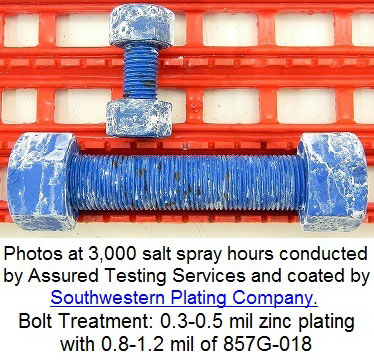

The fasteners below were pretreated with electro plated zinc and applied in accordance with ASTM-B633 Class SC1 including a deposit of 0.3 mils. To improve adhesion of the topcoat, zinc phosphate was applied. These fasteners exhibited less than 15% red rust after 3,000 salt spray hours.

Teflon™ coatings have been improved to provide environmentally friendly fluoropolymer systems that combat the most corrosive environments. One of the newest Teflon™ offerings is a truly water-based one coat system that provide excellent corrosion resistance. These coatings are specifically designed for coating off shore, chemical processing, and water treatment fasteners on substrates such as carbon steel, stainless steel, and aluminum.

| Manufacturing Benefits | NEW Teflon™ Technology | Typical Fastener Coatings |

|---|---|---|

| VOC Emissions¹ | < 3.0 lbs/gal | 2.84 – 5.2 lbs/gal |

| Water Clean Up | Yes | No |

| Flast Dry Temperature | 302° F (150° C) | 212° F (100° C) |

| Bake Schedule | 450° F (232° C) x 15 min | 400° F (204° C) x 15 min |

| Coefficient of Friction | 0.05 – 0.22 | 0.05 – 0.10 |

| Salt Spray Test² | 1000 hours | 800 hours |

| Salt Spray per SP11C³ | > 3000 hours | > 1500 hours |

| Wear Resistance (mg/kg Kcycles) | 45 – 55 | 48.8 |

| Hydraulic Fluid Exposure | 90 days no change | N/A |

| UV Exposure⁴ | 10.42% loss | 43.88% loss |

| Rig Wash Exposure (24 hours) | 24 hours no change | N/A |

| Kesternich DIN 50018 | 30 plus cycle w/ no change | 30 cycle w/ no change |

| ¹ VOC less exempt as calculated per US regulations. ² ≤ 5% red rust. Substrate tested is carbon steel. ³ ≤ 10% red rust. Fastener tested is carbon steel with 0.3 mils zinc plate. ⁴ 12 months simulated weathering. Tested per SAE J1960. |

||

For more information, contact Chris Dohl at 302-366-8530. Download a PDF of the marketing material for these coatings here.

There are certain technical requirements when applying Teflon™, therefore registration is required to purchase Teflon™ coatings and gain access to Teflon™ Fact Sheets and SDS Information. Click here to register for an account. If you are already a registered user, sign in to see SDS and Fact Sheets and to purchase.

Click here to see the full list of Intech Services Authorized Fastener Coaters. These fastener coaters have met strict standards and testing requirements proving their ability to apply the coating in a way that maximizes the coating’s performance and have the equipment necessary to apply and test the product to specification.

Availability: Next day shipping

Ordering: Online, fax, and phone

SDS and Fact Sheets: Click here to view and download.

SDS and Fact Sheets: Login or register to view.