Micro-Tek, of Cinnaminson, New Jersey, specializes in custom drawing, stranding and insulating, cutting and stripping of fine wire and cable .0009” (AWG #50) and larger. Chemours fluoropolymer resins (Teflon® PTFE, FEP, PFA , Tefzel® ETFE and ECCtreme®ECA) are extruded on various nonferrous, ferrous, plated, unplated, thermocouple and alloy wires in single end, concentric, roped and bunched configurations. Extruded walls as thin as .0035” and made with Teflon® PTFE are just one of the precision engineered products.

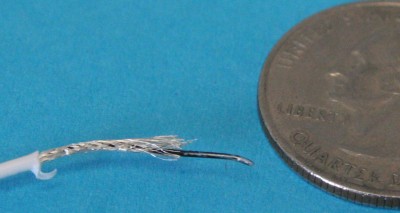

Micro-Tek was asked to meet a customer’s specification that required an ultra fine stranding for flexibility as well as thin wall insulation to meet dimensional constraints. (0.005” ± .0005”)

Micro-Tek drew, stranded and annealed silver plated OFHC copper to produce a soft #42/750 (0.0033”) strand. This strand provides a higher flexibility and flex life than a single strand.

|

|

Using Teflon® PFA fluoropolymer resin, Micro-Tek was able to achieve the customers desired OD. Using extruded PFA allows for a consistent, high quality product in a variety of colors. The PFA insulation’s excellent mechanical, electrical and thermal properties make this insulated strand ideal for a variety of applications and environments with tight dimensional constraints.

As a custom manufacturer, Micro-Tek Corp’s operation is designed to accommodate specific customer requirements. One product that demonstrates a broad range of Micro-Tek’s manufacturing capabilities is a 50 Ohm low noise micro-coaxial cable.

This product requires stranding the SPC before insulating it with Teflon® PTFE to the specified diameter. A low noise coating is applied to the insulated strand, which is then braided with a (95% coverage) SPC shield. Finally the cable is jacketed with Teflon® FEP to the customer’s required diameter.

Example of Thin Wall Ultra-Fine Stranding |

Please contact us for more information on our product line and manufacturing capabilities.

Click Here to download a copy of this article.

Applied Plastics Corporation was founded in 1965 and has evolved into a full service fabric and belting OEM supporting a broad range of industries and end use applications

An ISO-9001 certified company.

1748 Woodmont Drive

Tuscumbia, AL 35674

(205) 383-6700